Hot plate

A heated plate fuses thermoplastic materials via direct contact providing a strong, controlled and straight-forward bonding process.

Hot plate

Simple and intuitive

Compliant

Full electric

Economic

Modular

Durable

Hot plate applications

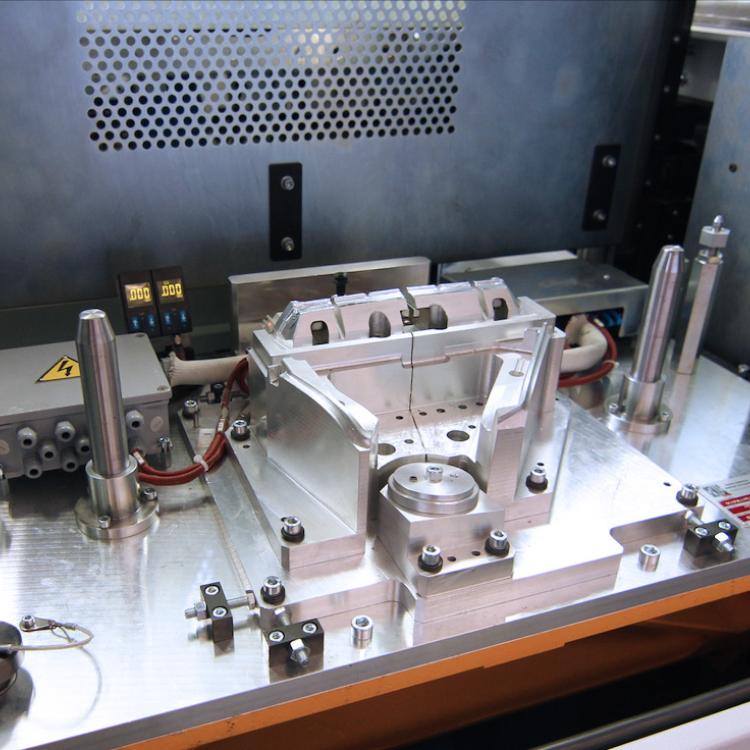

We design and build custom welding tools that seamlessly integrate with our machines. These tools are tailored to your specific components, ensuring precise and efficient welds.

Hot plate welding tools is the most appropriate solution for welding medium or large-sized components which must be water-tight, air-tight and, in general, leak-proof, like tanks and pipings.

The hot plate welding process is fully electric and tools are always equipped with top class materials and components. For this reason, hotplate technology ensure the highest welding standards in terms of flexibility, quality and cost-effectiveness.

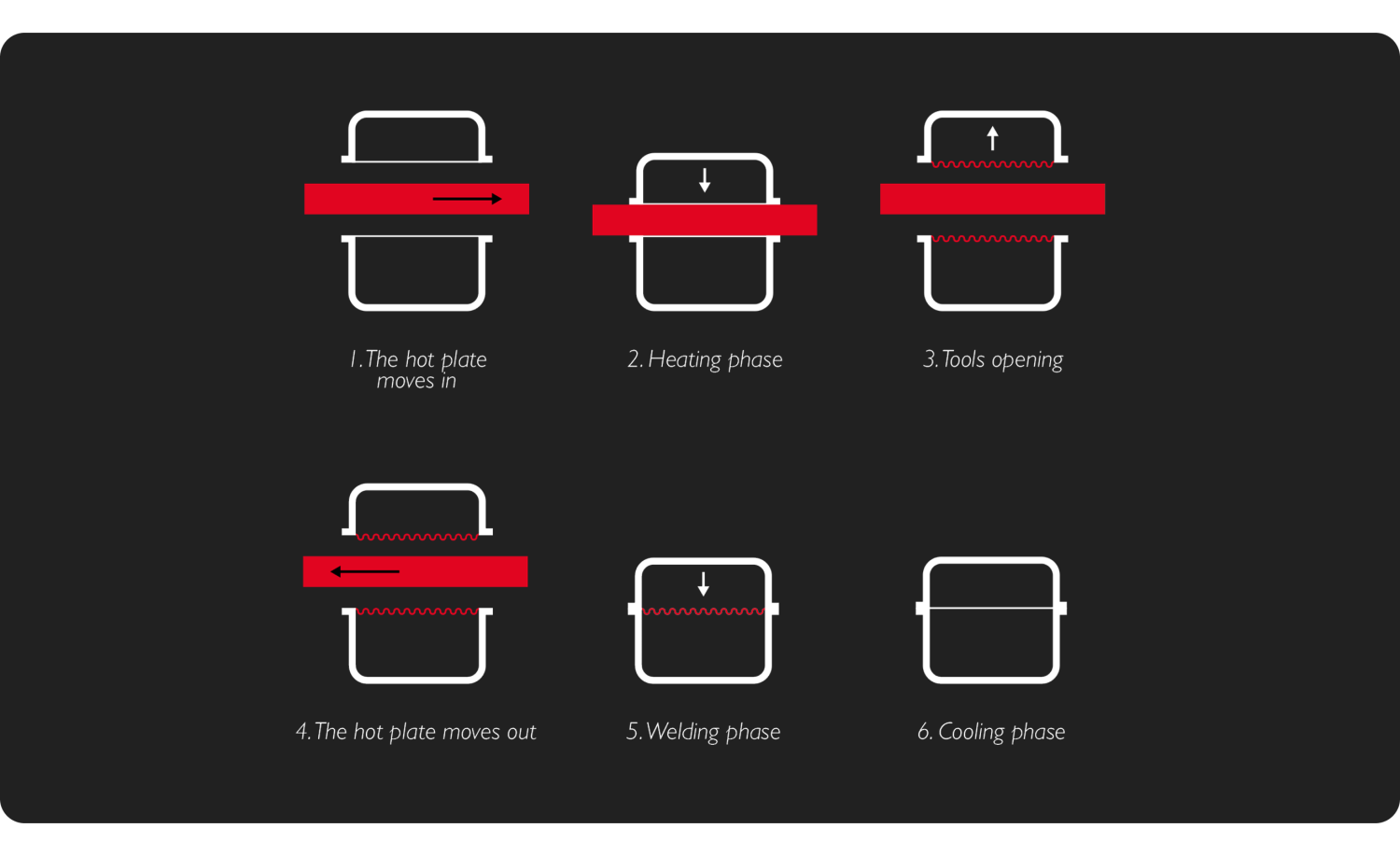

Process overview

How it works

A heated plate, maintained at a temperature higher than the melting point of the materials being joined, is placed between the two components. The surfaces of these parts are pressed against the hot plate for a set period, allowing the material to melt at the interface. Once the heating time has passed, the hot plate is quickly removed and the two components are pressed together to form a strong weld. This pressure creates a slight bead, or “weld flash” around the joined area, reinforcing the bond.

How it is built

To address common challenges in hot plate welding, such as molten material adhering to the plate, CEMAS has introduced several technical solutions.

The hot plates can be coated with a non-stick layer, typically Teflon, or crafted from materials like steel or specialized bronze alloys. It is also possible to keeping the plate clean by increasing its temperature in such a way any residue vaporizes.

What it is suitable for

Hot plate is the most appropriate solution for welding medium or large-sized components which must be water-tight, air-tight and, in general, leak-proof, like tanks and pipings. Smaller hot plate machines can also address aesthetically demanding applications, like rear lamps, gloveboxes and storage.

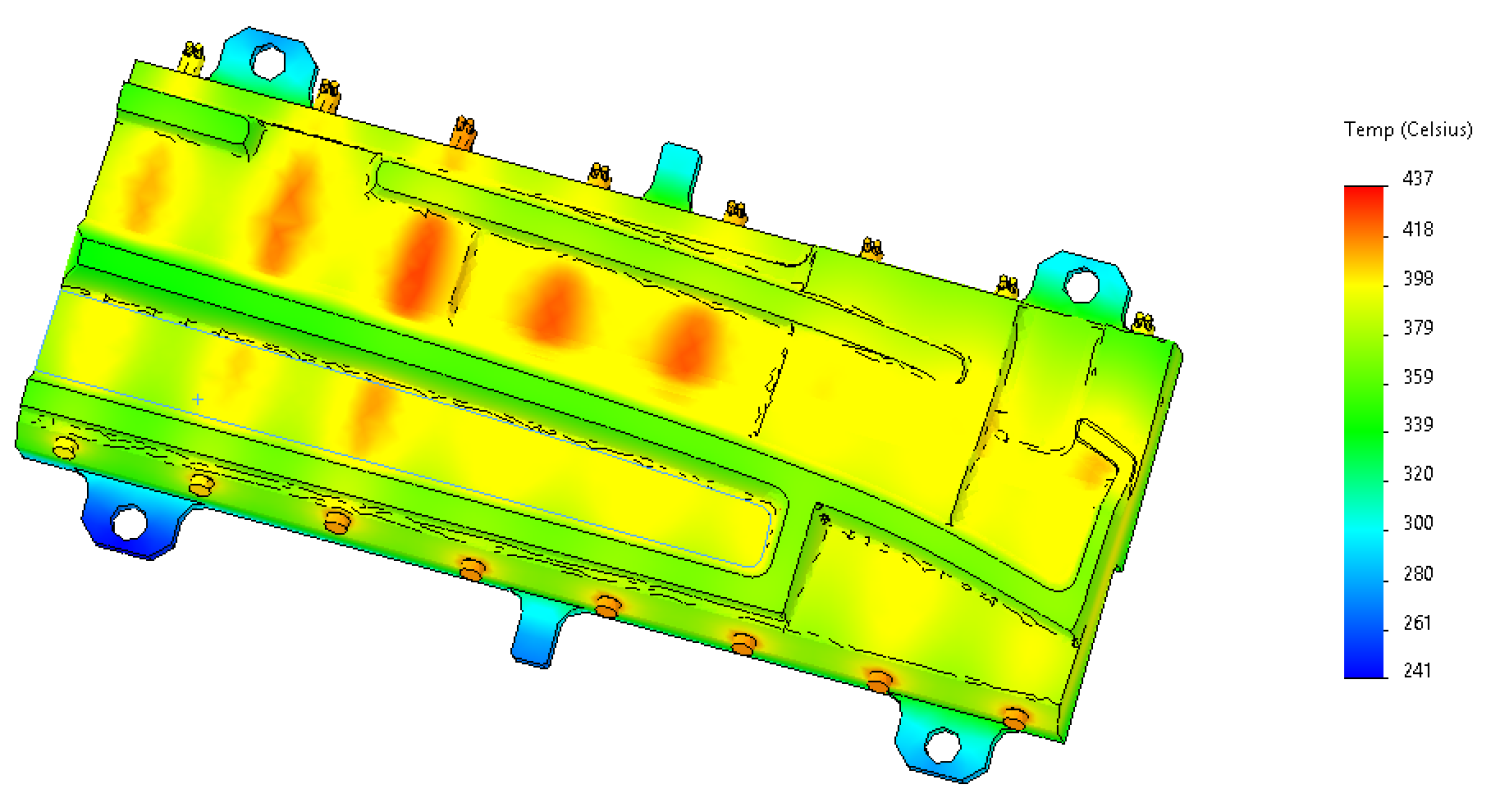

Modular architecture

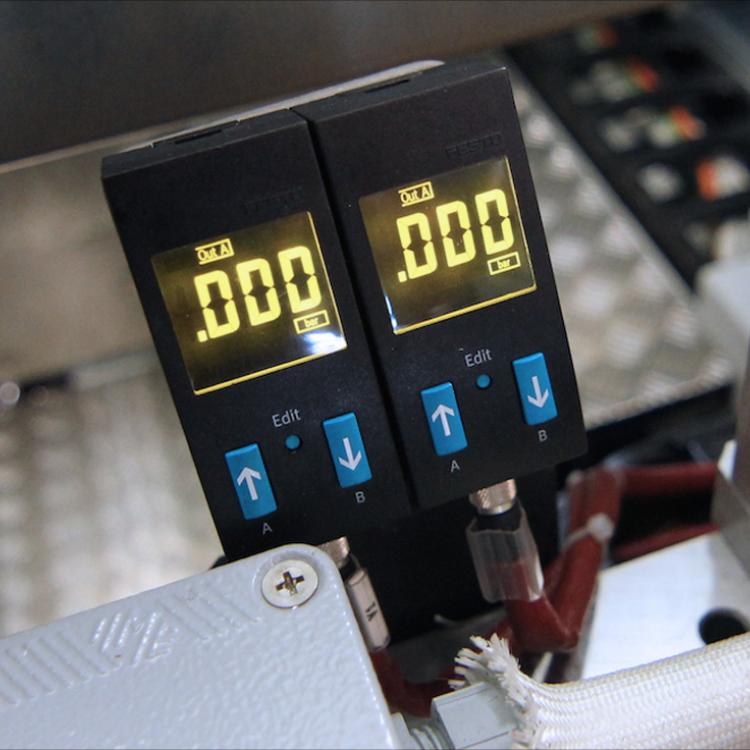

The welding tool features multiple heating zones, strategically laid out and built into the hot plate itself, mapped and programmed individually via the intuitive CEMAS HMI. The programmed setting and cycle are stored into the tool’s memory in order to ensure reliability.

Tool manufacturing and virtual modeling

As for any welding technology, hot plate tools are custom-designed and manufactured in order to optimize both the production process and the overall performance of the welded part. The two pieces to join are contained in the respective welding fixtures and the automatic hot plate welding cycle is fine-tuned by setting both the heating and cooling times. Working pressure and set temperatures are also crucial parameters involved in thermoplastic welding through the hot plate.