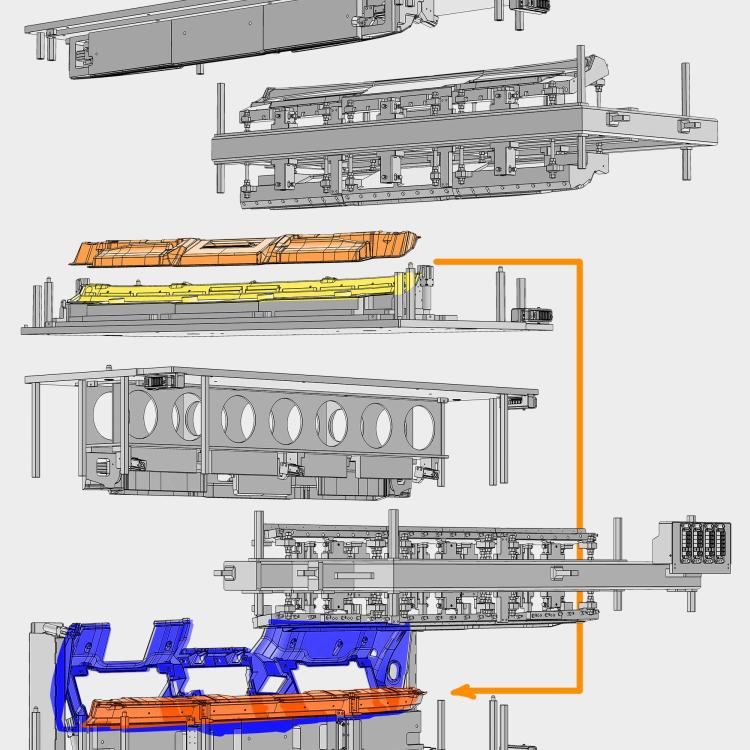

A compound, two-step welding process, enabled by two dedicated welding tools

This large dashboard is obtained by first welding together the two halves of the air duct and then joining the result to the outer dashboard itself.

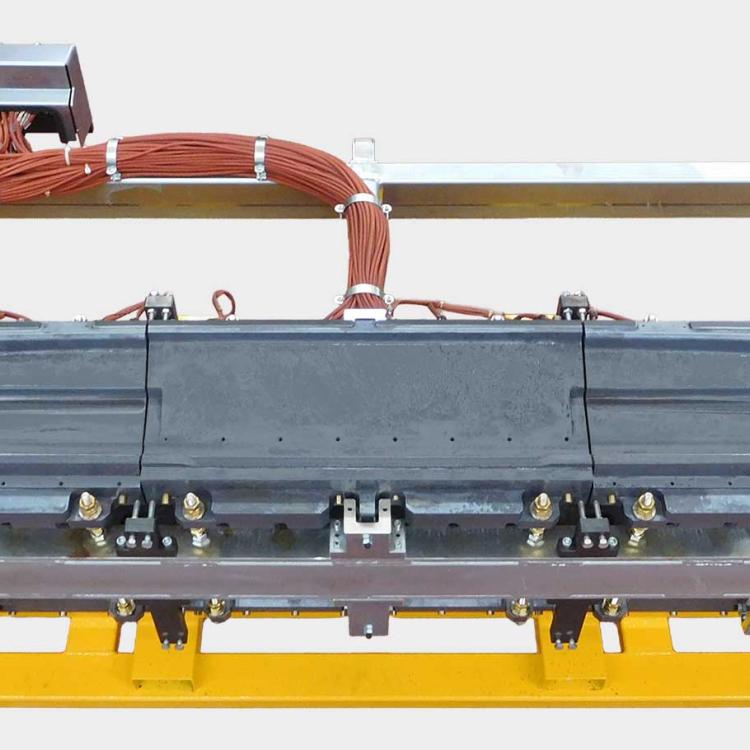

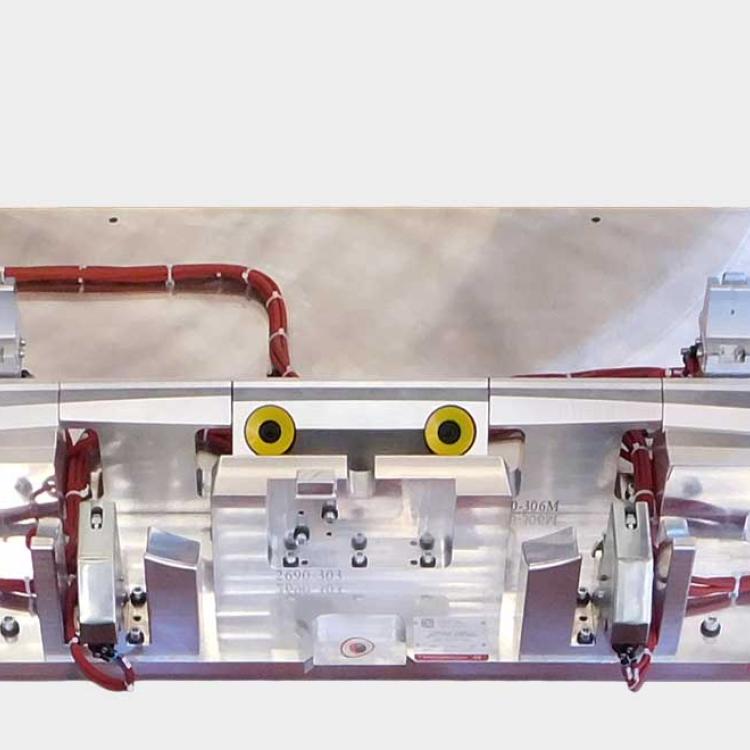

In order to enable this process, two respective welding tools were designed and manufactured; both tools are compatible with the same hot plate welding machine.

Each welding instance has its own requirements: one is focused on air-tightness, the other on preserving component aesthetics. For this reason, the respective materials and finishes — namely, aluminum, steel and Teflon coating — were chosen accordingly.

As for any CEMAS hot plate solution, tool change is fast and automated; plus, despite its large size, the whole system allows for easy maintenance over the production span.