Ultrasonic

A sonotrode joins thermoplastics through high-frequency vibrations, delivering fast, precise and cost-effective bonds with clean, repeatable results.

Ultrasonic

Versatility

Speed

Full electric design

Quality first

Safety

Customizable process

Ultrasonic applications

We design and build custom welding tools that seamlessly integrate with our machines. These tools are tailored to your specific components, ensuring precise and efficient welds.

Ultrasonic welding machines must always be designed and "shaped" based on the material and the geometric characteristics of the components that have to be welded.

Some of the most important world automotive brands have relied on CEMAS ultrasonic welding machines to join their products.

Process overview

How it works

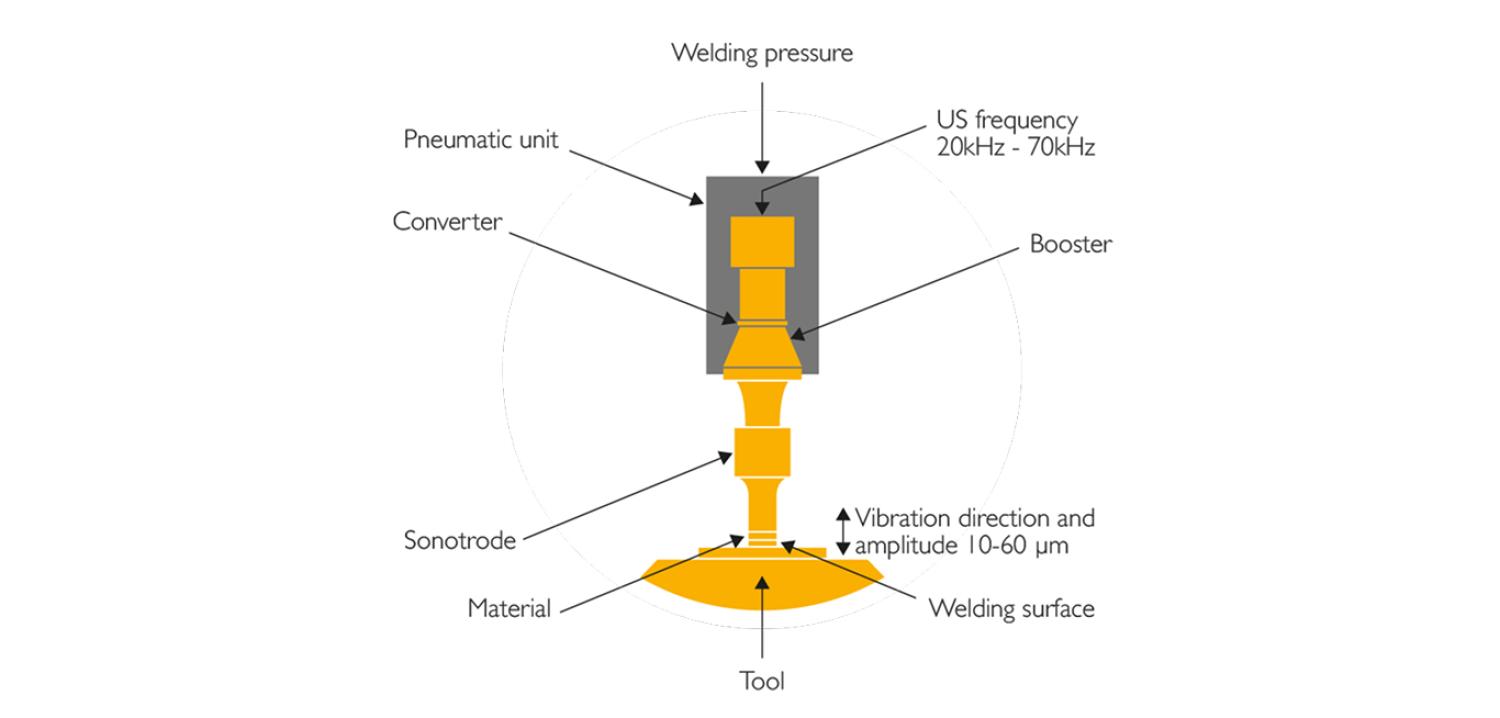

The process operates by converting friction and vibration energy into heat using a welding tool called "sonotrode." High-frequency ultrasonic vibrations, generated by the ultrasonic system, are transferred to the components at the joint interface. This energy melts the contact point between the parts, creating a strong and clean bond. The fully electric ultrasonic machines developed by CEMAS ensure unmatched precision, speed and cleanliness, with enhanced control over welding parameters such as energy, force and depth. The rapid cooling process and absence of curing requirements further enhance efficiency.

How it is built

The system for performing welding with ultrasonic technology is composed of a generator, a converter, a booster (if applicable) and a sonotrode. All these elements work at resonance frequency.

What it is suitable for

Ultrasonic welding remains highly competitive due to its versatility, flexibility and cost-effectiveness. This technology is ideal for applications requiring fast, precise and reliable bonding of thermoplastic components, particularly for parts that do not need simultaneous welding of the entire path.