Vibration

An imposed vibration fuses thermoplastic surfaces through friction, creating strong bonds without external heat.

Vibration

Total vibration control

Soundproof structure

Compact yet complete

Wide rear opening

Always available

High memory storage

MK2: a new generation

The state of the art of CEMAS vibration welding technology. MK2 (Mark 2) means even more precision, reliability and traceability for mass production, thanks to cutting-edge upgrades both to the machine design and engineering.

Now featuring the New CEMAS HMI, developed in-house from the ground up in order to guarantee a consistent experience and to access useful information in the most intuitive way.

Vibration applications

We design and build custom welding tools that seamlessly integrate with our machines. These tools are tailored to your specific components, ensuring precise and efficient welds.

Vibration welding tools can handle any type of component, from small parts to large, complex assemblies, making them ideal for diverse industrial applications. Their systems allow for rapid tool changes, customizable settings, and hybrid options combining infrared technology.

Additionally, the technology is versatile enough to accommodate a wide range of component designs, ensuring strong, clean welds across all applications. Advanced ergonomic solutions and real-time tuning capabilities further enhance their user-friendliness and reliability.

Process overview

How it works

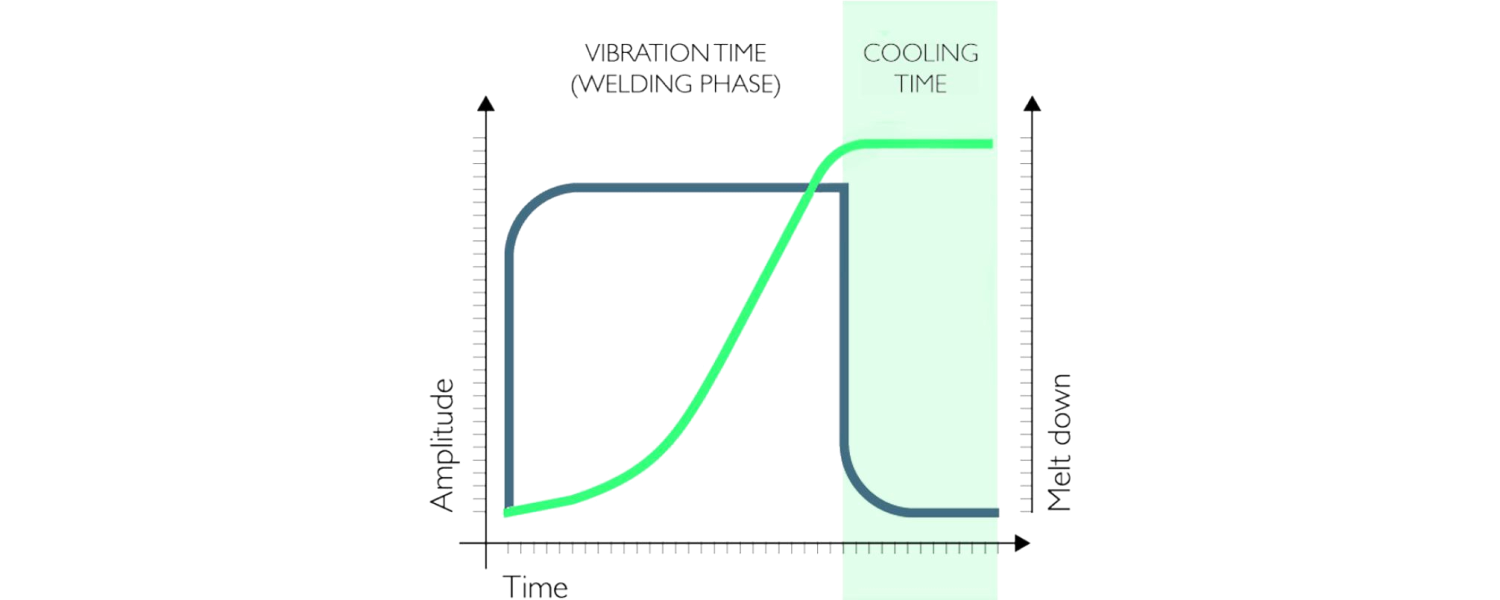

The joining of thermoplastic materials via vibration welding is carried out by melting the two surfaces in contact. This welding method creates a seam for which there is no need to supply heat from the outside: it comes from the transmission of the frictional energy produced by the two components. The local temperature increase melts the welding perimeter of the two pieces to be welded.

How it is built

The vibration technology is based on our latest series of vibration generator. The machine adapts the vibration frequency in real time following the mechanical feedback of the vibrating system. The result is a cleaner and more efficient vibration than the one obtained with older systems.

What it is suitable for

Vibration welding technology is highly suitable for joining large and complex plastic parts that require robust and durable connections. It is commonly used in industries such as automotive, electronics, and appliances where precision and reliability are crucial.

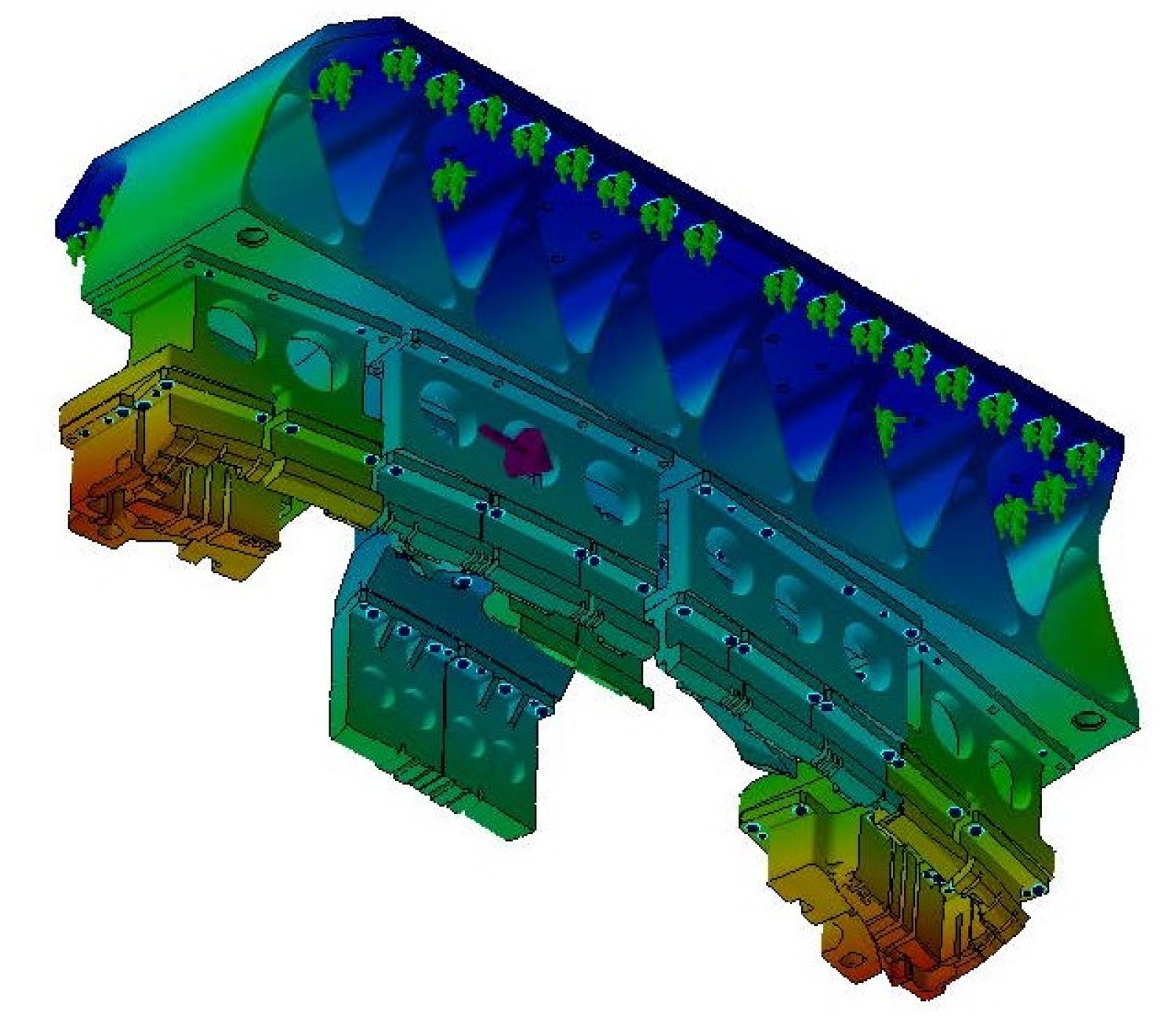

Tool manufacturing and virtual modeling

In order to meet such a high standard, our machines are designed to optimally manage all the welding process variables. The tool manufacturing is preceded by a careful virtual modelling and prototyping process. Our engineers can simulate how the systems respond to the imposed vibration, by using finite element analysis software.