912

(240 Hz)

Born hybrid

Power supply

(50HzThree-phases+N+GND)

400 V a.c.

Max. power required (peak load)

(kW)

27

Vibration amplitude

(mm)

0,4 ÷ 1,8

PP equivalent welding area

(cm²)

400

Upper tool weight (max.)

(kg)

75

Vibration plate dimensions

(mm)

945 x 540

Clamp net force [gross]

(kN)

18 [23.3]

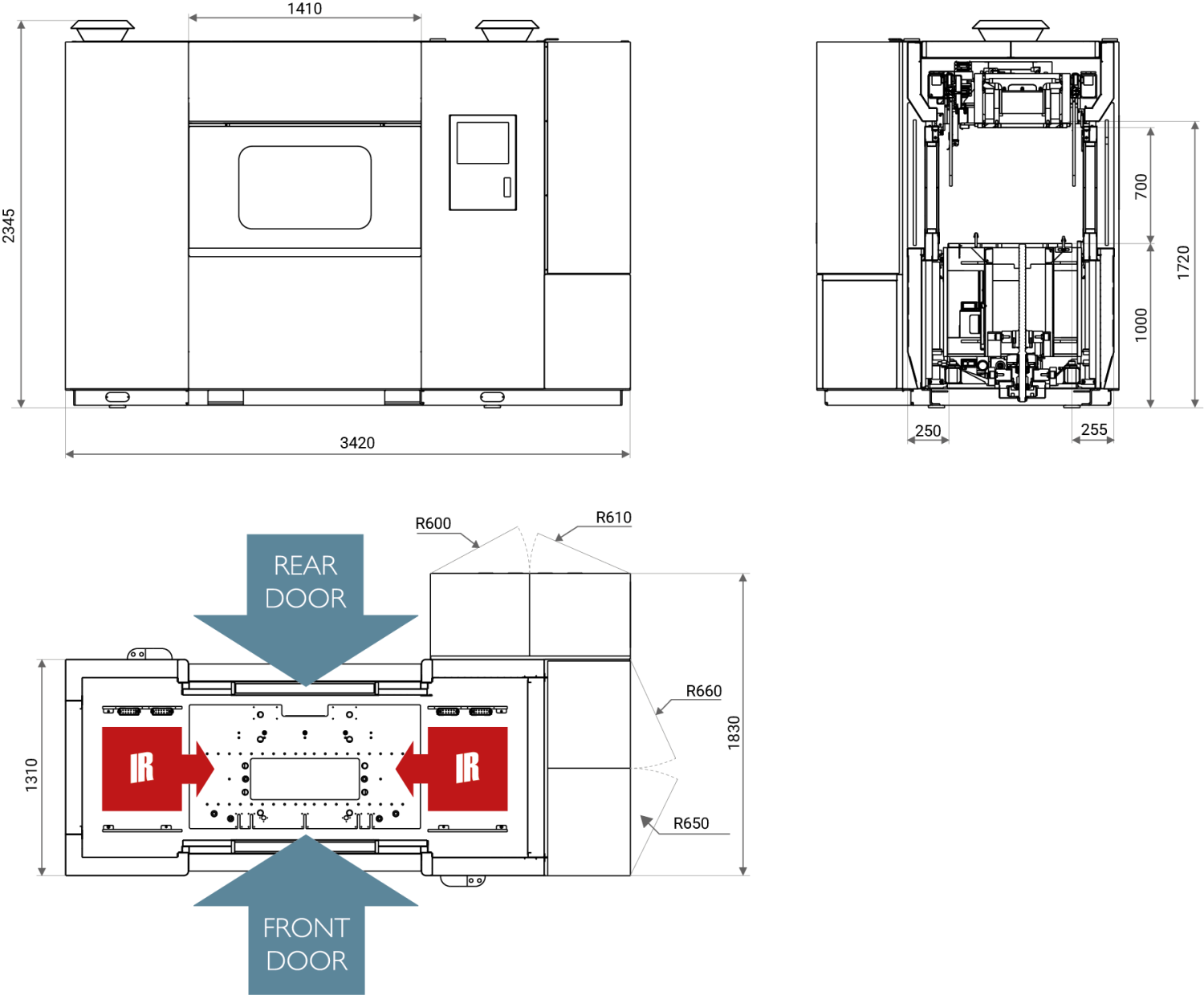

Overall dimensions

(mm)

3420 x 1830 x 2345

Total weight

(kg)

6200

Data-sheet

912 combines two of the most complex welding technologies, vibration and infrared, within an optimized design.

It is equipped with infrared emitters, housed on the right and on left of the table, so the rear of the machine is clear and customizable with a rear sliding door. By interfacing with anthropomorphous robots, it can achieve significantly reduced cycle times. All the movements are driven by servo-controlled motors: this allows the machine not only to meet the highest standards of cleanliness, but also to achieve unmatched levels of speed accuracy.

Its hybrid nature, both extremely versatile and very precise, makes this machine a one-of-a-kind.

Power supply

(50HzThree-phases+N+GND)

400 V a.c.

Max. power required (peak load)

(kW)

27

Vibration amplitude

(mm)

0,4 ÷ 1,8

PP equivalent welding area

(cm²)

400

Upper tool weight (max.)

(kg)

75

Vibration plate dimensions

(mm)

945 x 540

Clamp net force [gross]

(kN)

18 [23.3]

Overall dimensions

(mm)

3420 x 1830 x 2345

Total weight

(kg)

6200

Data-sheet