Gluing

A specialized adhesive, precisely applied, joins thermoplastic materials, ensuring a flexible, precise, and heat-free bond.

Gluing

Flexibility

No limits on materials

Cost efficiency

Aesthetic precision

Durability

Customizable process

Gluing applications

We design and build custom welding tools that seamlessly integrate with our machines. These tools are tailored to your specific components, ensuring precise and efficient welds.

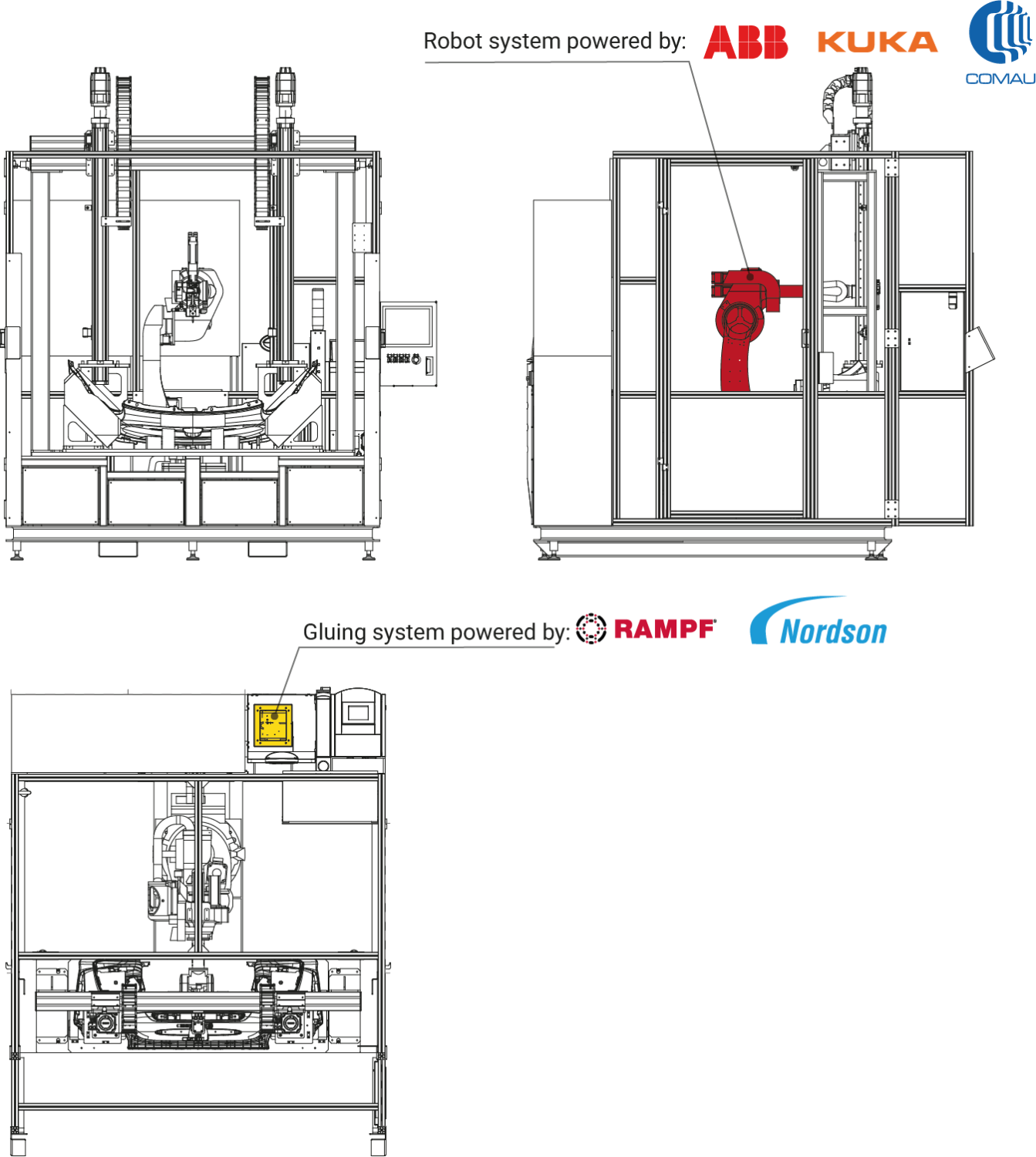

Gluing is the only technology that allows to join together different types of plastic materials, even those whose chemical composition normally does not allow the welding process. This technology is particularly suitable for joining bumpers, trims, spoilers or any others component that visually must not show imperfections. The glue distribution, performed by an anthropomorphic robot, ensures a high flexibility of the process.

For this reason, famous automotive brands have relied on CEMAS gluing machines to achieve high-aesthetic-rate results for their top of the range products.

Process overview

How it works

The gluing machine allows thermoplastic parts, which cannot be welded, to be joined using adhesive. The gluing machines are equipped with a robotic arm, equipped with a nozzle, which precisely applies the adhesive along the gluing path. The dosage is controlled to ensure uniformity and repeatability of the process. The system is managed by a centralized controller that monitors all parameters.

What it is suitable for

The gluing technology is ideal for applications requiring robust, seamless bonding of plastic components with high aesthetic and structural demands. In specific conditions, plastic gluing is the only technology capable of meeting certain joining standard requirements. CEMAS gluing machines, being fully electric, deliver exceptional results in terms of speed, quality, and cost-effectiveness.