Laser

A powerful, concentrated radiation fuses thermoplatic materials by exploiting their own properties, forming precise and strong bonds.

Laser

Adaptive

Aesthetic

Modular and scalable

Fast as light

Simple and clean

In-depth thermal control

Laser applications

We design and build custom welding tools that seamlessly integrate with our machines. These tools are tailored to your specific components, ensuring precise and efficient welds.

Laser welding tools can handle any type of component, in terms of dimensions and complexity, across multiple industry spheres. The specific features of laser welding are readily met with precise, adaptive fixture movements and flawless holding cavities, which deflect the radiation into the most uniform welding seam.

Our cutting-edge technology and precise machinery work in synergy to accomodate even the most sensible parts, adopting a "soft-contact" approach, that minimizes stress on the material; therefore, we deal with components that shall not be strained in any way.

Process overview

How it works

Laser is a optoelectronic phoenomenon: an amplified and then concentrated light radiation at a specific wavelength, potentially manifesting as a narrow, continuous beam as well as its punctiform projection.

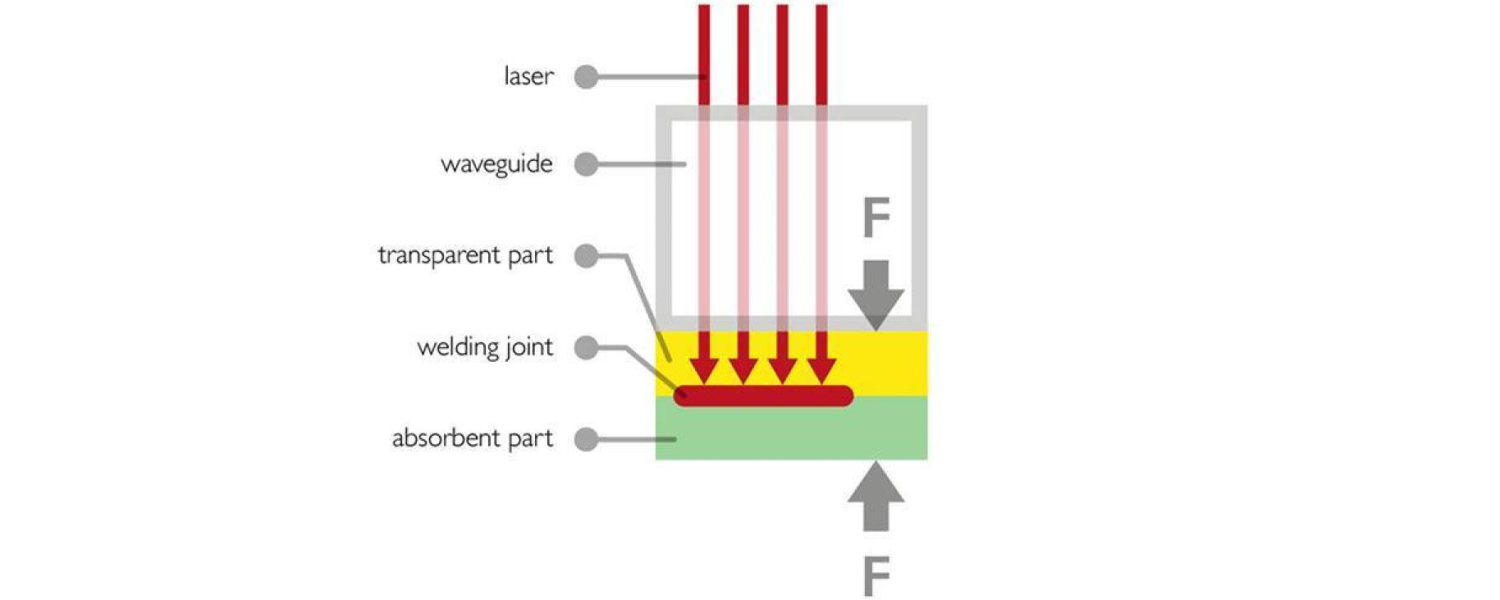

Using the "diode laser system", the welding process with laser irradiation allows to join a plastic absorbent component to a transparent one, meaning so in regard to the specific wavelength used.

In the welding process, the laser joins two elements making up the component: the transparent one carries on the light without being altered while the absorbent part is irradiated by that light. Once reached the melting point the absorbent component, according to the principle of conduction, heats the transparent one, allowing the actual welding. The laser is previeously guided by waveguides, which turn a light bundle into a consistent seam.

In the meantime, to ensure a perfect welding and sealing quality, the two components are tightly pressed together.

How it is built

Our laser unit consists of a powering group, which includes the diode source, and a transmission system, based on optical fibre.

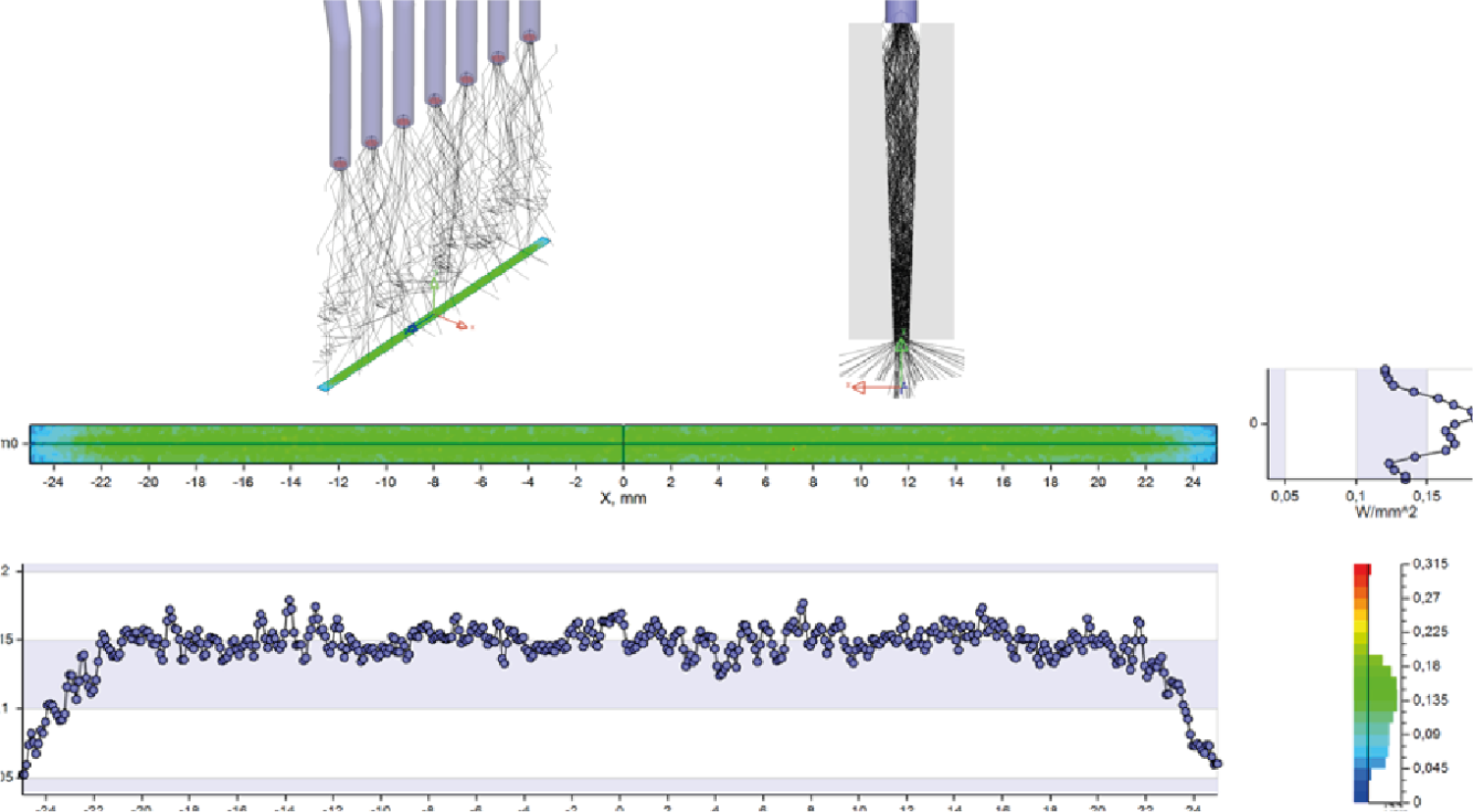

The laser beam emitted by the diode is collimated onto the surface lens of the fibre and then split and directed to the welding area. The optical fibre beams are called "bundles".

Modular architecture

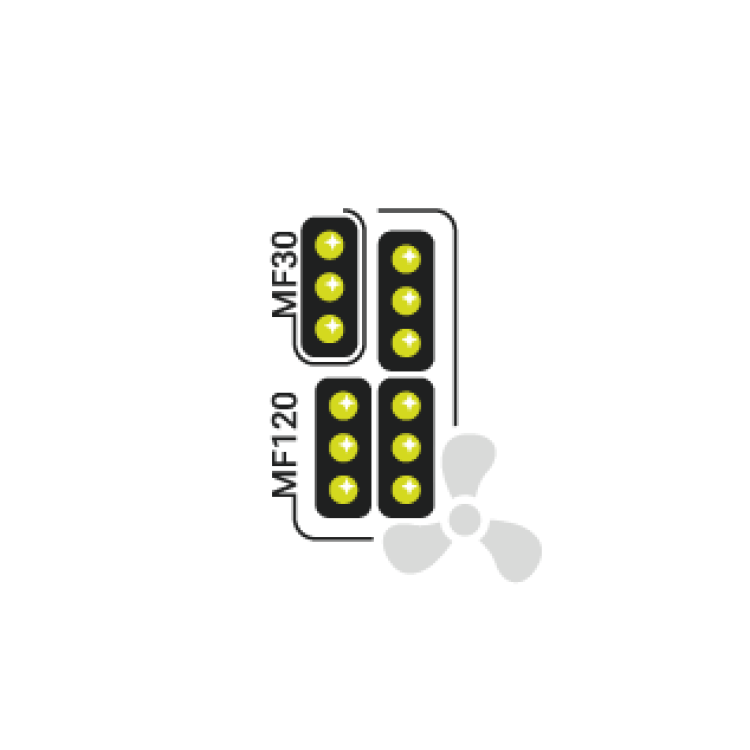

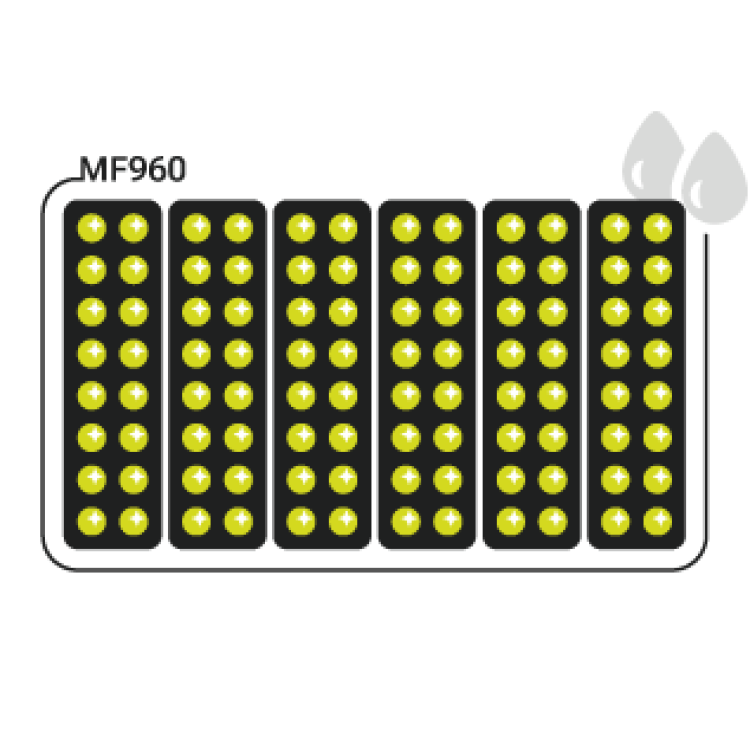

Our multifibre laser technology consists in a fully modular architecture, allowing for high levels of customization to meet stringent production requirements. The modular system permits customers to start with a specific number of laser sources and add more as needed. This flexibility ensures a precise estimation of the necessary sources for specific products, guaranteeing optimal efficiency with no compromise on quality.

Laser sources standard layouts

Tool manufacturing and virtual modeling

In order to meet such a high standard, our machines are designed to optimally manage all the welding process variables. The tool manufacturing is preceded by a careful virtual modelling and prototyping process. Our engineers can simulate how the light acts in the waveguide, by using finite element analysis software.