Laser Welding Technology for the Audi A5 – Precision Meets Design

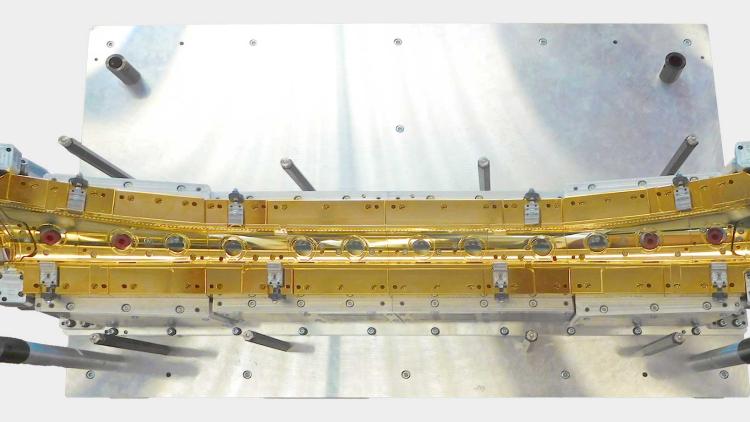

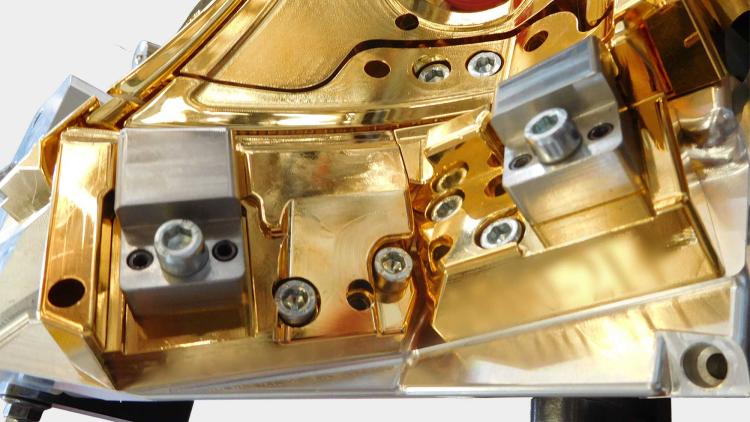

The rear lamp of the Audi A5 embodies a modern design approach where aesthetics and technical performance must coexist without compromise. The component features a high-transparency lens and an inner LED module, resulting in a highly visible welding line that demands absolute precision and visual cleanliness.

Laser plastic welding is the ideal solution for this application, offering a non-intrusive, soft-contact process that preserves the optical clarity and surface quality of the lamp. The welding interface is carefully optimized in terms of materials and transparency to ensure flawless results.

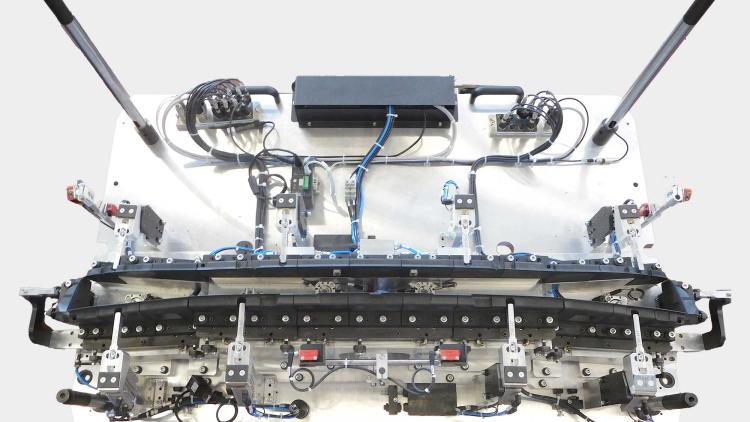

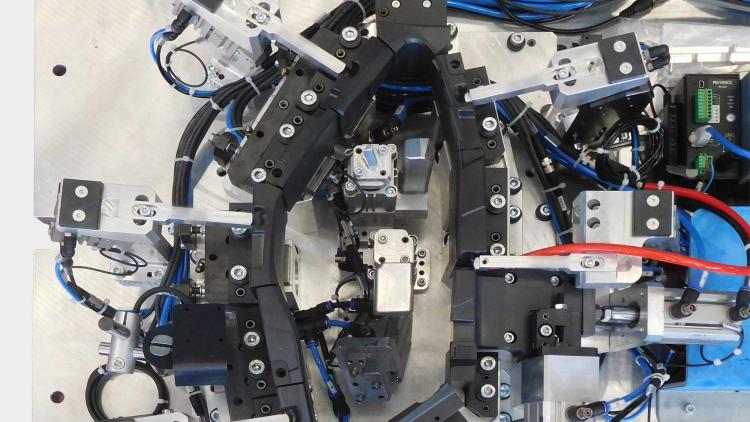

To guarantee process control and full traceability, the welding system integrates advanced presence detection sensors and serial code readers—ensuring that each part meets strict automotive standards for quality and reliability.