Staking

An infrared heating and a precision staking are combined to offer efficient, clean and visually flawless solutions for thermoplastic assembly.

Staking

Secure Joints

Process monitoring for quality

Surface protection

Cost-effective

Safe and non-invasive

Reliable and repeatable

Staking applications

We design and build custom welding tools that seamlessly integrate with our machines. These tools are tailored to your specific components, ensuring precise and efficient welds.

InfraStake welding is ideal for assembling thermoplastic components with visible surfaces, complex geometries, or sensitive materials that require clean and controlled processing. The process ensures strong, aesthetic, and repeatable joints without vibration or surface damage.

Leading global automotive manufacturers have chosen CEMAS InfraStake solutions for critical interior and exterior assemblies.

Process overview

How it works

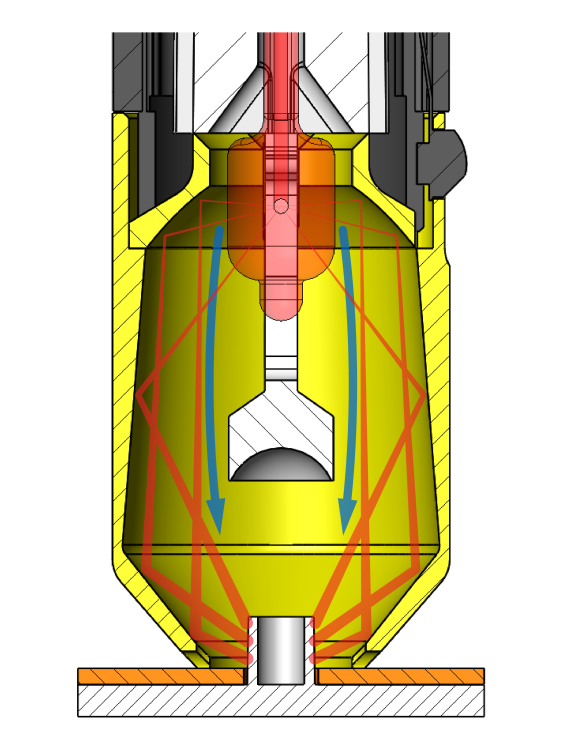

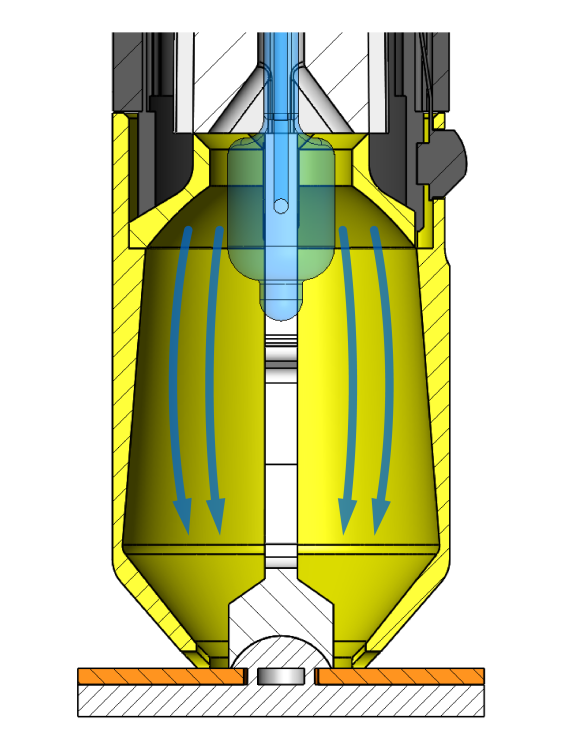

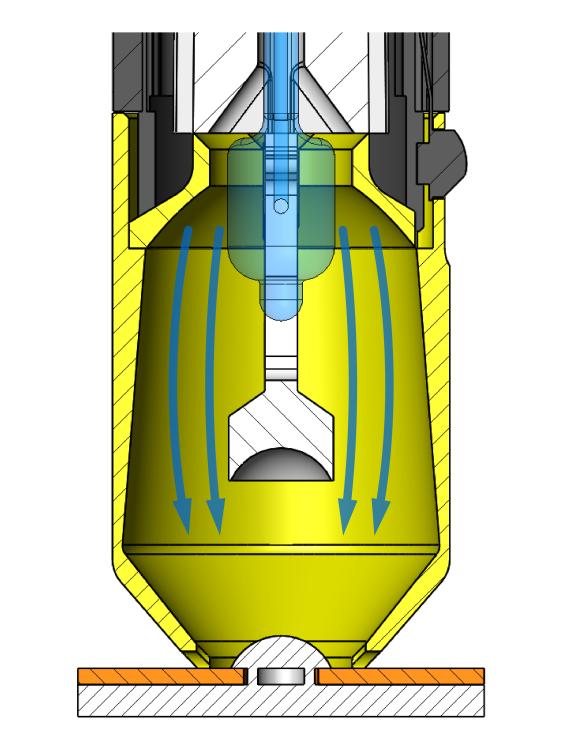

The process uses infrared light as the energy source to soften a molded plastic boss. Once the boss reaches a semi-molten state, a forming tool reshapes it into a cap or stake, mechanically retaining the mating component. This controlled, low-impact process avoids surface damage and ensures consistent, high-quality results. InfraStake is designed for bosses of various sizes and geometries, making it highly adaptable to different design needs.

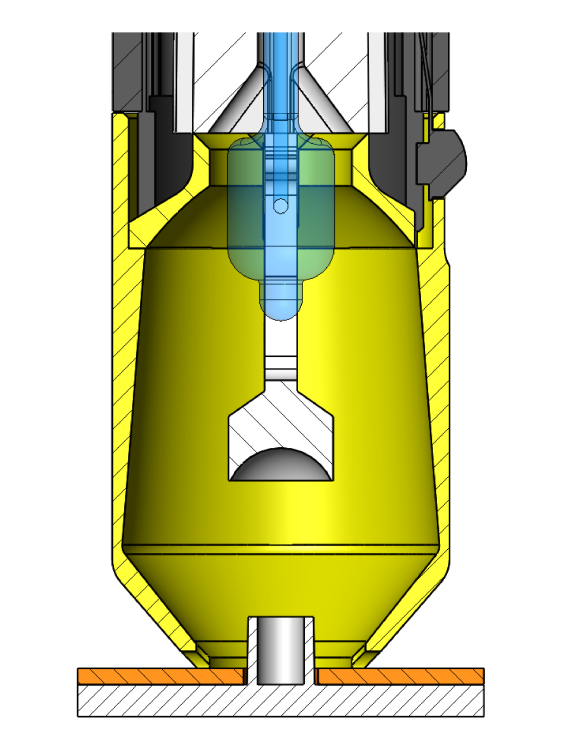

How it is built

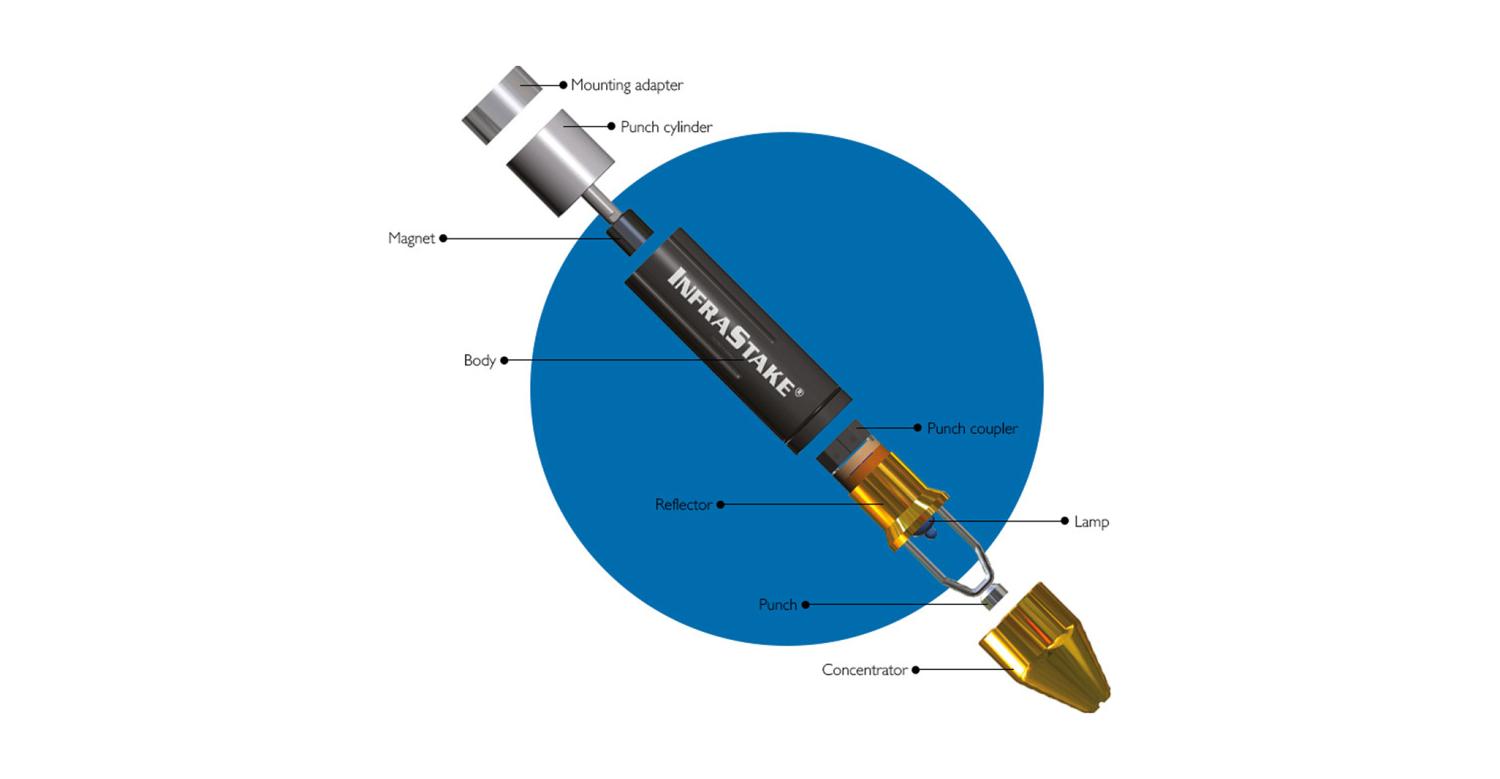

An InfraStake module consists of four main elements: an infrared heat source, a reflector that focuses the energy on the thermoplastic boss, a cooled forming pin, and a linear actuation system. The IR source specifically heats the plastic, while the pin shapes the molten material to create the joint. Immediate cooling stabilizes the shape and ensures repeatability. Each module is designed for efficiency, precise process control, and compatibility with various geometries.

What it is suitable for

InfraStake is a revolutionary infrared-based staking process, offering a non-contact alternative to ultrasonic staking technology. It is ideal for joining thermoplastic components across various industries, including automotive, medical devices, electronics, and consumer goods. InfraStake is highly suitable for sensitive PCB assemblies, delicate medical components, large automotive interior parts, and LED lighting applications, where traditional staking methods may cause damage or aesthetic defects.