Infrared

An infrared radiation fuses thermoplastic materials by using heating waves, offering a precise, controlled and contactless joining method.

Infrared

Design flexibility

High and smart precision

Efficient and energy saving

Non-contact and clean

Modular design

Memory storage

Infrared applications

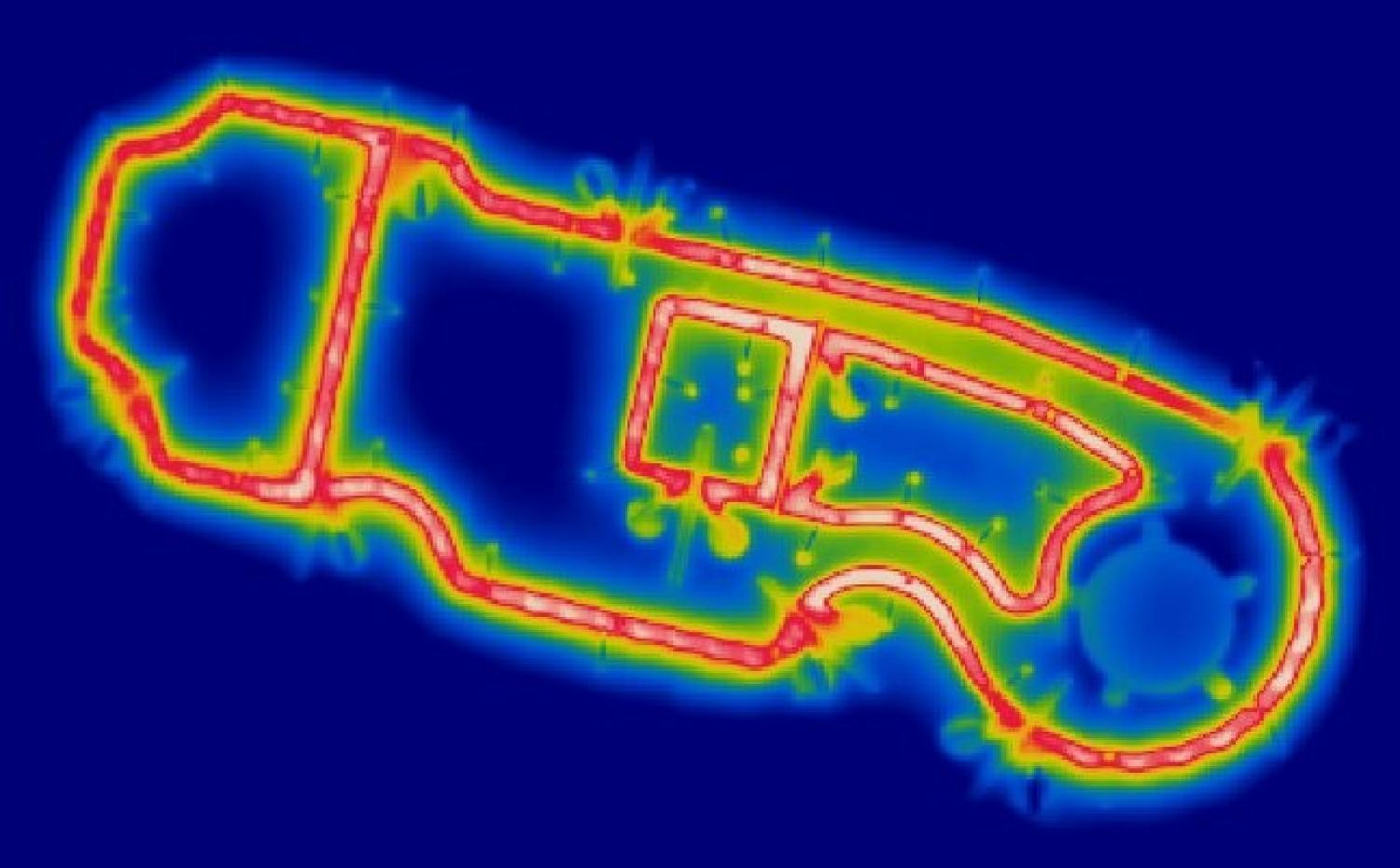

We design and build custom welding tools that seamlessly integrate with our machines. These tools are tailored to your specific components, ensuring precise and efficient welds.

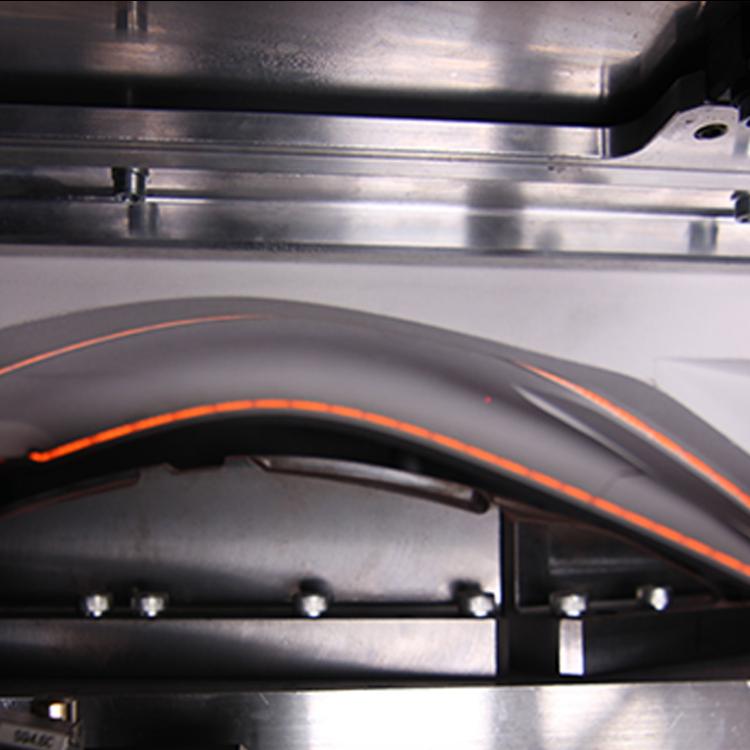

Infrared welding tools can handle any type of component, from small parts to large, complex assemblies, making them ideal for diverse industrial applications. Their systems allow for rapid tool changes and customizable settings.

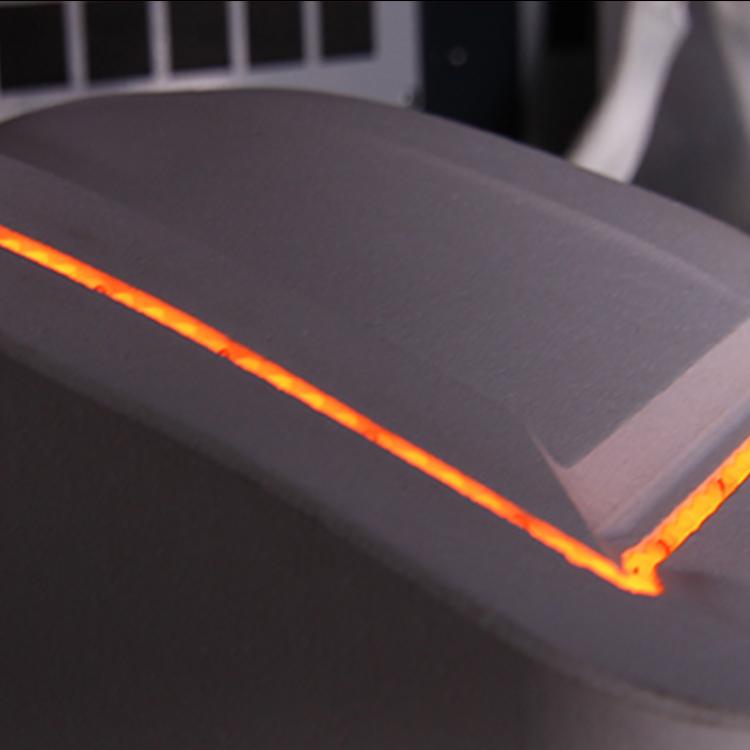

The infrared welding process ensures to weld new heat-sensitive materials, thanks to non-contact irradiation. Individually controlled zones allow to follow the welding profile of the component resulting in a really high design flexibility.

Process overview

How it works

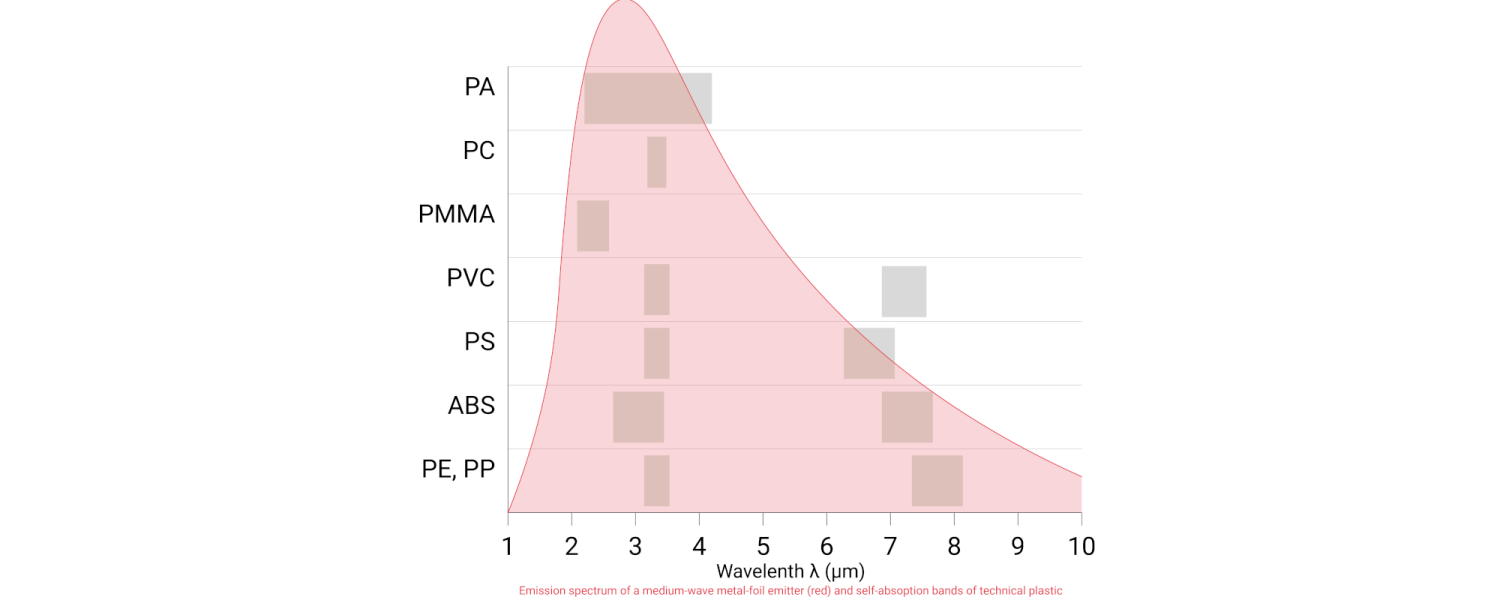

The infrared welding process uses medium-wavelenght emitters to irradiate the surfaces of components without direct contact.

The irradiation phoenomenon strictly depends on the emitter's power and is extremely sensible to its distance from the heated component.

Each IR zone is individually controlled for precises heat manangement, reducing deformation. The standby feature enhances energy efficiency between operations.

How it is built

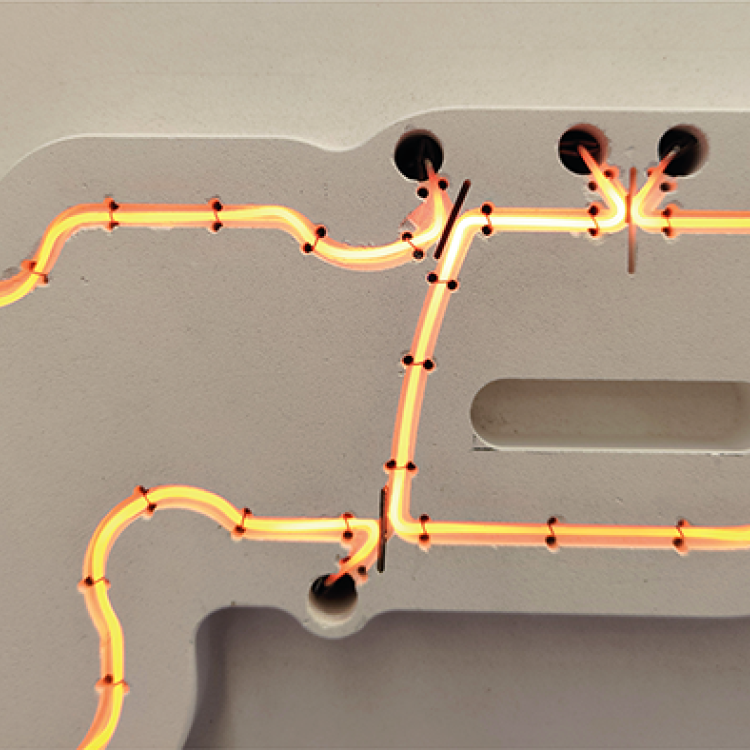

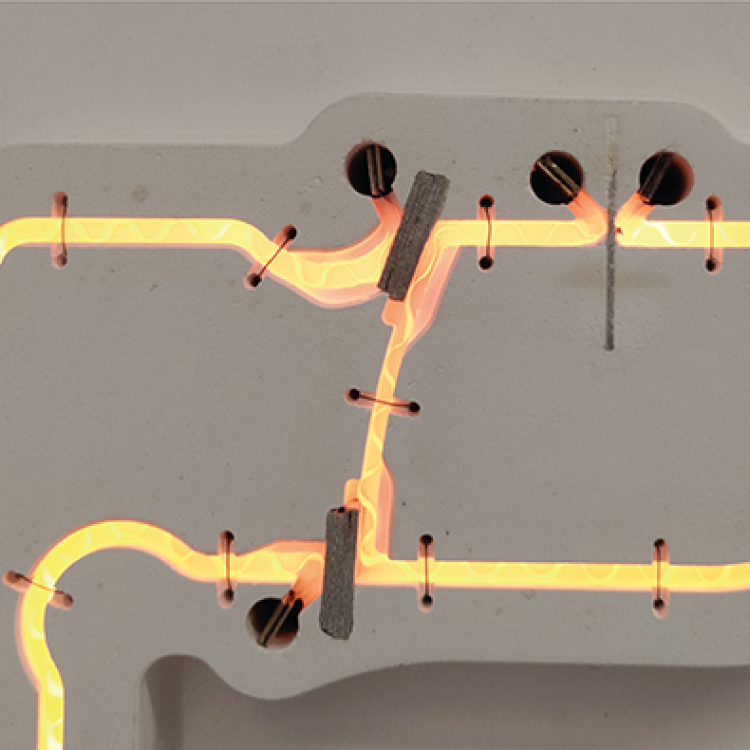

Emitters with metal coil are embedded into ceramic substrates and manufactured to exactly follow the welding profile, allowing a really high design flexibility. They are not fully enclosed and this significantly increases the efficiency of the emission. The welding zones are controlled and managed individually and each emitter is operated by its own controller: IRM4.0 (Infrared Module). This feature is particulary important when dealing with heat-sensitive parts.

What it is suitable for

Infrared technology is ideal for welding plastic materials that requie clean and strong bonds, particulary components where design flexibility and aesthetic quality are essential. It can weld parts of various sizes, thickness and difficult-to-join materials.

Tool manufacturing and virtual modeling

An infrared mirror is essentially composed of a ceramic body in which the resistors that produce the infrared waves are embedded.

A thermal radiation can be produced with a heating resistance material (NiCr or CrFeAl) and suitable electrical values. Depending on the thermal properties of the material, values of current, tension and distance from the source need to be defined.

As a general rule, the electrical power needed to heat the component gets more and more efficient as resistance increases and distance decreases.

Modular architecture

The core of our innovative system is the IRM4.0 , a microprocessor-based device able to separately manage four different channels, in order to perform an optimal use of each metal conductor. This unique feature dramatically optimizes space management, maintaining a high output power.

The IRM control modules are powered by specifically designed power units. Even the electrical power system is completely modular and can be freely configured based on your specifical power needs with virtually no limits.