Vibration + Infrared

An infrared preheating with an imposed friction fuses thermoplastic parts by combining contactless heating with mechanical motion, ensuring cleaner and stronger bonds.

Vibration + Infrared

Dual-phase process

Clean and strong joints

Lower stress, better results

Time and energy optimization

Advanced process control

All-in-one configuration

Vibration + Infrared applications

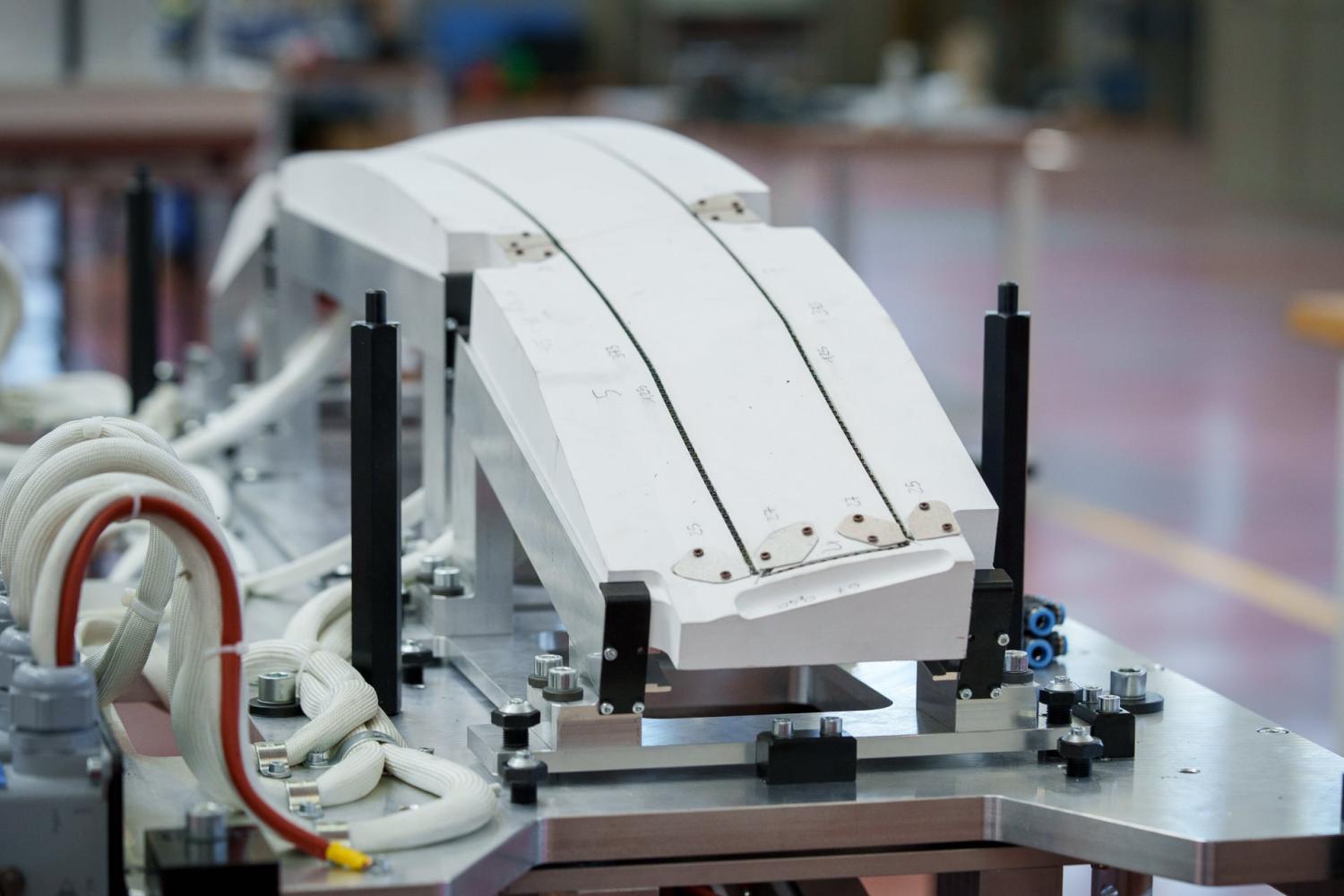

We design and build custom welding tools that seamlessly integrate with our machines. These tools are tailored to your specific components, ensuring precise and efficient welds.

Hybrid infrared and vibration welding tools are ideal for components requiring both high aesthetic quality and mechanical strength. This combined process allows clean, contactless preheating followed by friction welding, enabling strong, precise joints even in complex geometries or with delicate materials.

Flexible control of both heat and motion ensures consistent results, making the technology suitable for demanding applications across various industries.

Process overview

How it works

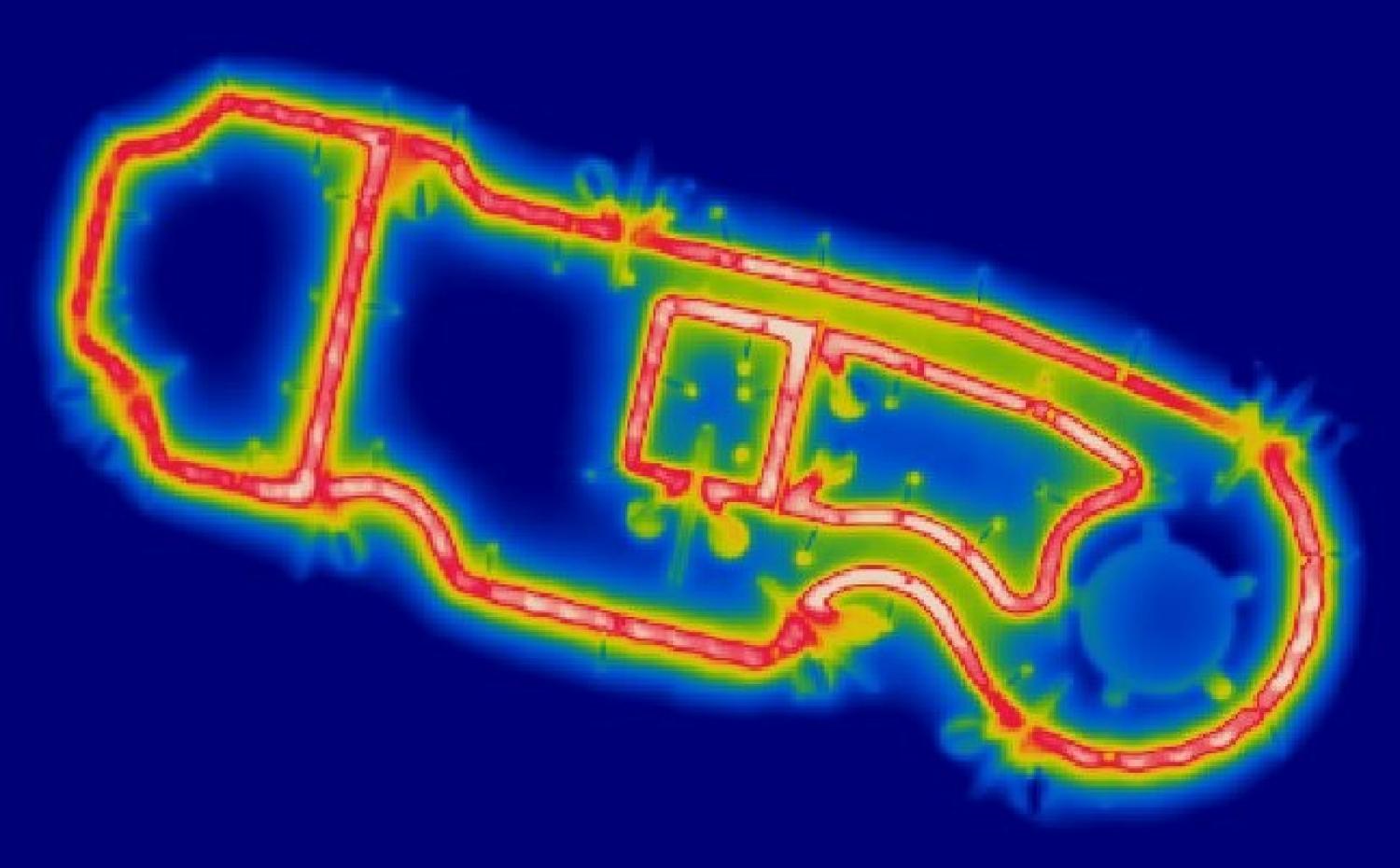

Hybrid welding combines infrared preheating with vibration welding. In the first phase, infrared emitters apply non-contact heat to soften the welding surfaces. This prepares the material for the vibration phase, which then creates friction and pressure to complete the weld. The combination ensures strong, clean joints with minimal flash and reduced particulate generation.

How it is built

Hybrid welding machines integrate two systems into a single, compact structure: an infrared module for precise, programmable heating, and a vibration unit for mechanical joining. Both systems are independently controlled, allowing for fine-tuning of temperature, pressure, and timing. The machine architecture is designed for fast tool changes, and ergonomic operation. The hybrid tooling includes custom-designed IR mirror, CNC-machined to follow the weld path where resistive filaments are embedded. The filament emits infrared radiation precisely along the weld rib, ensuring uniform and controlled preheating. This tool configuration enables fast, repeatable results while accommodating even complex geometries.

What it is suitable for

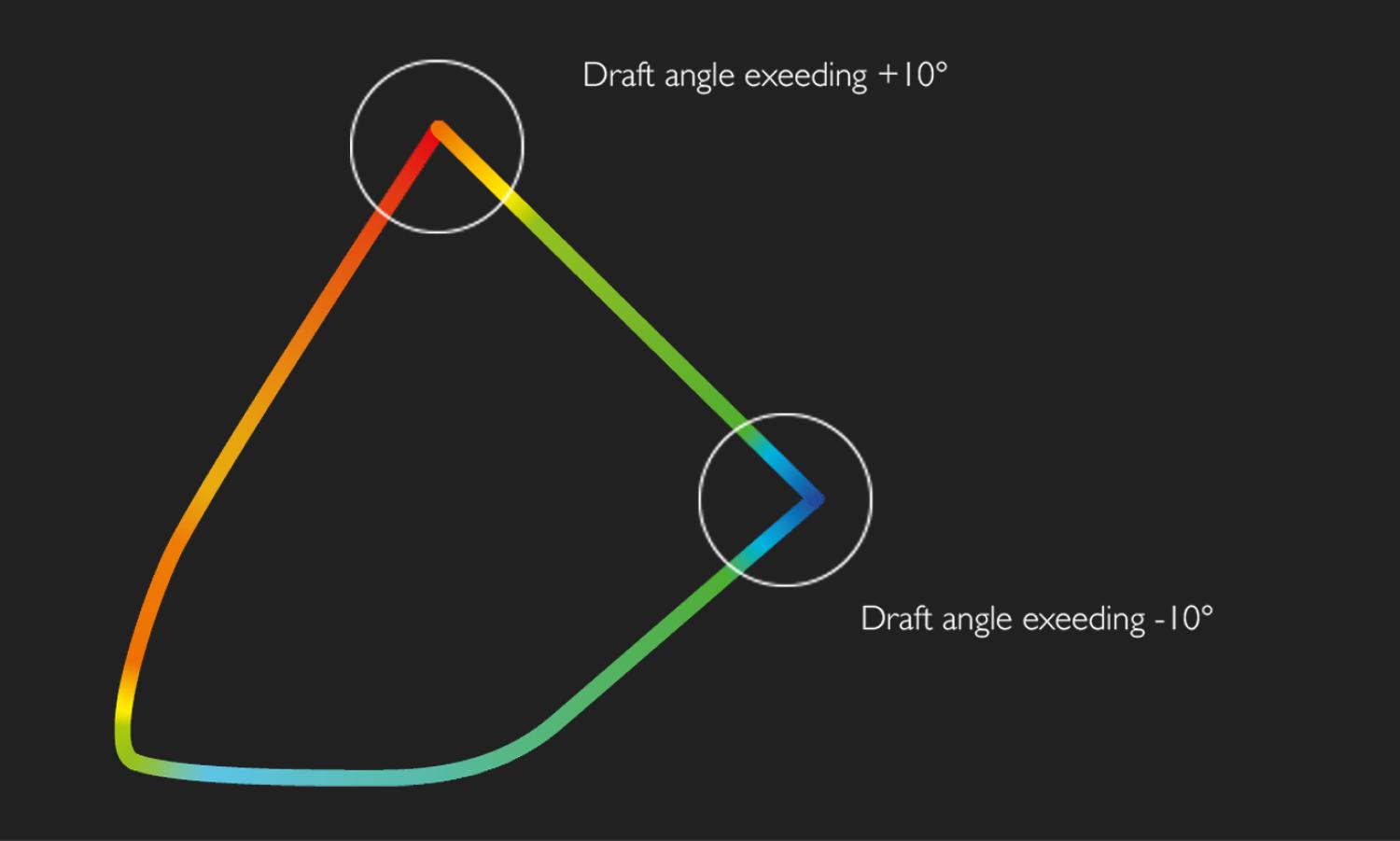

Hybrid welding is ideal for applications that require both mechanical strength and visual quality. It is particularly effective for components with complex geometries, including parts with draft angles up to ±25°, which exceed the capabilities of traditional vibration welding. The technology is widely used in the automotive industry, large industrial components, and any application where both durability and appearance are critical.

Tool manufacturing and virtual modeling

Custom tools are designed and built to match each component's shape and material. Virtual modeling allows engineers to simulate the welding process in advance, optimizing heat distribution, weld paths, and vibration settings. This ensures maximum performance and repeatability from the very first production cycle.

Advantages

- Reduced flash and dust. The IR preheating phase softens the weld surfaces, reducing frictional wear and minimizing flash formation and airborne particles.

- Improved aesthetics. Lower mechanical stress and less vibration reduce surface marks and deformation, resulting in cleaner weld lines.

- Superior strength. Pre-softening with infrared allows for more consistent melt and fusion, enhancing joint integrity and long-term durability.

- Better handling of complex parts. The process accommodates components with intricate shapes and deep draft angles, expanding design freedom.

- Lower post-processing needs. Clean joints and reduced flash significantly decrease the need for finishing operations.