Precision and compactness: the perfect equipment for the BMW GS airbox

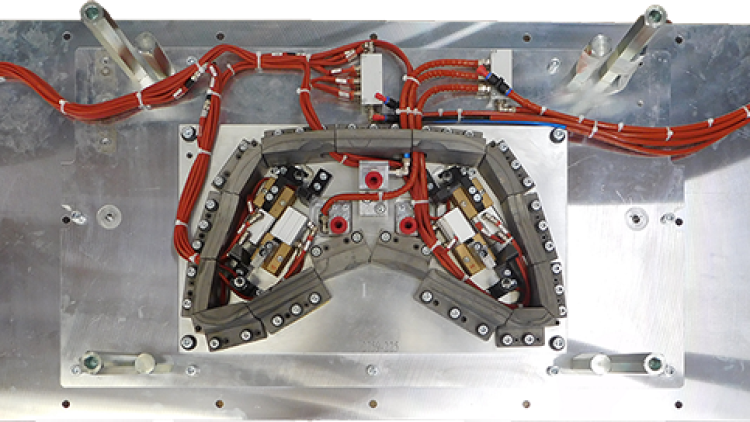

For the BMW GS airbox, CEMAS developed a custom hot plate welding system designed to deliver strong, airtight, and dimensionally precise joints—even in applications with complex geometries and space constraints. This solution is ideal for plastic components in motorcycle engine systems where performance and sealing are critical.

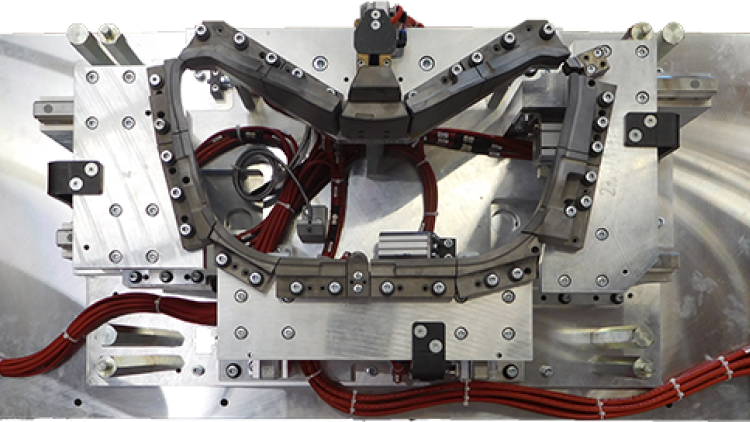

The welding equipment was specifically engineered to fit into a compact machine footprint without compromising on weld quality, process stability, or long-term reliability. Developed in close collaboration with the customer, the system enables a one-step welding process that ensures high repeatability and consistent results across production cycles.

Ergonomics and user-friendly operation were key design priorities, making this solution both efficient and easy to integrate into modern manufacturing lines.