Reliability and precision for the Nissan Kicks rear lamp

For the rear lamp of the Nissan Kicks, CEMAS developed a custom hot plate welding solution designed to deliver strong, precise, and visually flawless joints between the lens and housing. Special focus was placed on aesthetic quality and long-term sealing performance—both critical for exterior automotive lighting components.

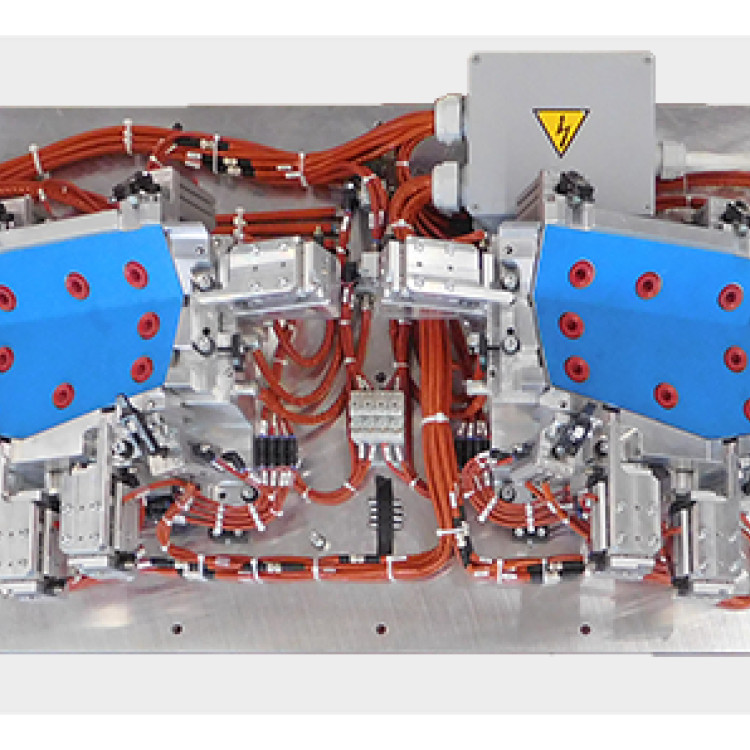

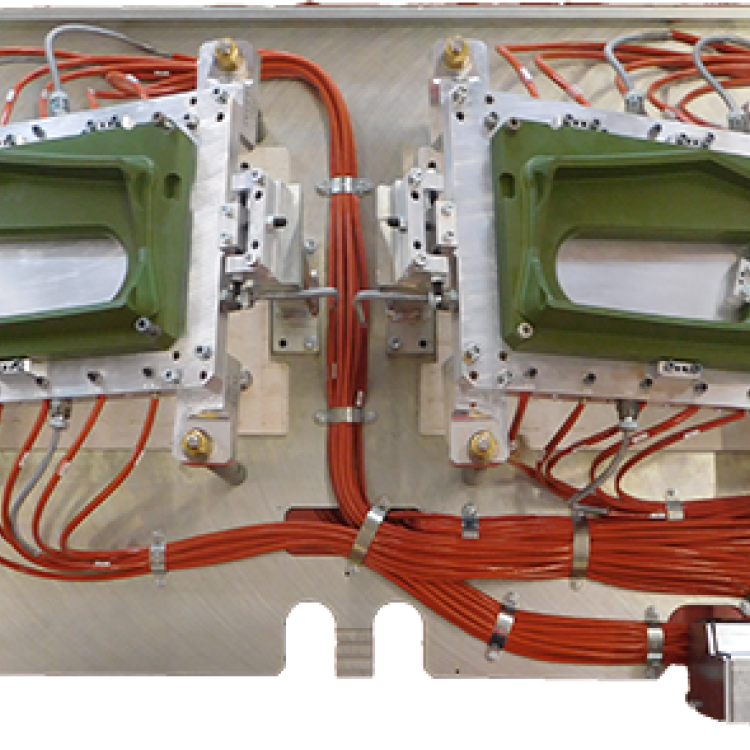

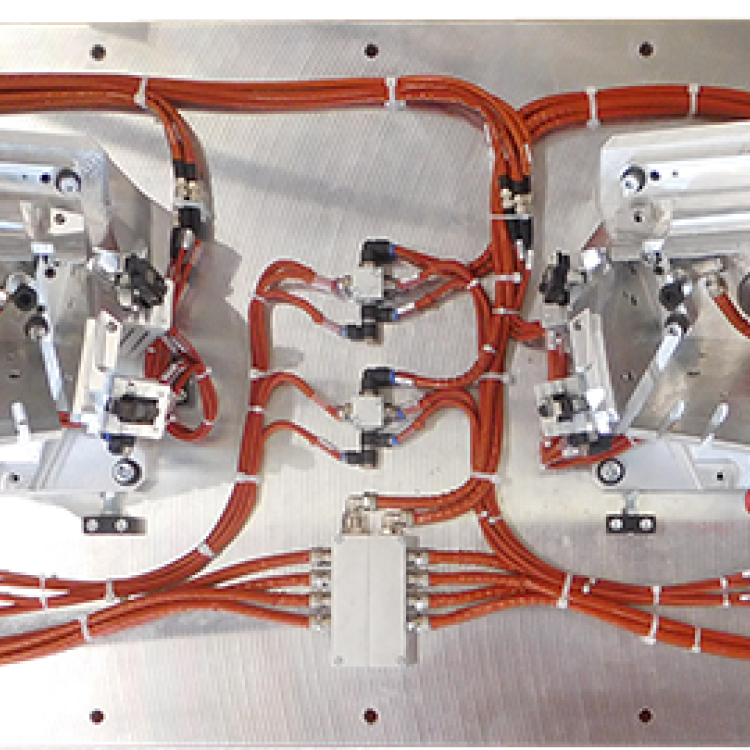

The project was implemented using CEMAS hot plate welding technology, an ideal solution for medium-sized plastic parts requiring high reliability and tight process control. The tooling was engineered to ensure perfect alignment, optimal heat distribution, and consistent weld quality across production cycles.

Additional features include flexible open configuration options, quick tool change systems, intuitive operator interface, and easy maintenance—making the setup both efficient and user-friendly for modern manufacturing environments.