-

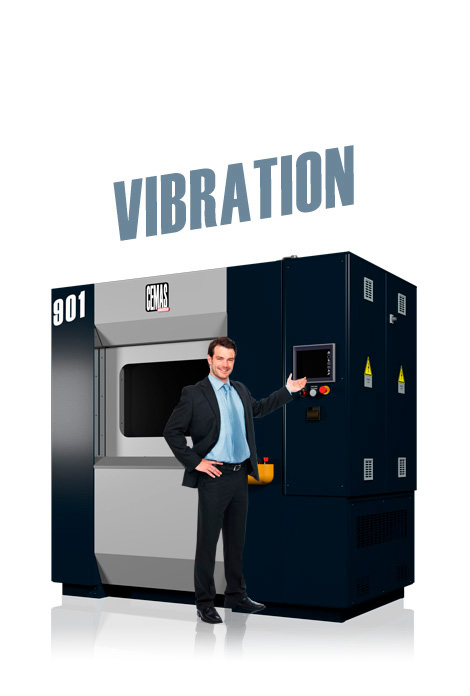

Vibration

Vibration welding is generally used on large parts, but also smaller components can be welded economically.

Discover products -

Infrared / Hot Plate

Infrared welding is recommended for the welding of reinforced high-performance plastics.

Discover products -

Gluing

In some specific conditions, plastic gluing is the only technology capable to ensure certain joining standard requirements.

Discover products -

Ultrasonic

Ultrasonic welding is much faster than conventional adhesives or solvents.

Discover products -

Infrastake

InfraStake does not use excessive heat or vibrate, which greatly reduces the risk of surface marking.

Discover products

- Highly customizable

- No compromise for quality

- Easy maintenance

- Ergonomic loading station

- Reliability

- Energy saving technology

- Innovative and user friendly UI

Cutting edge technology and fully equipped machines as standard. Discover more

-

Highly customizable

Many standard features included in our machines are optionals for competitors and, should this not be enough, just turn the page to discover a full range of over 60 optionals for your tailor-made machines. -

No compromise for quality

All components used by CEMAS are from world leading suppliers and never sub-brands.

Safety is our ultimate goal, as well as a prompt availability of spares worldwide. -

Easy maintenance

The use of the latest-generation electronic components has resulted in a remarkably smaller control panel, and in positioning the hydraulic unit below the control panel for the 240 Hz machines. This change has totally cleared an inner compartment and has made tooling maintenance and set up operations easier. -

Ergonomic loading station

Special care was devoted to the manual loading steps of the process, both for small and large machines: to minimize effort on the backbone, the loading/unloading area was kept as close as possible to operator. There are no machines of the same class available on the market where this distance is so small. -

Reliability

Light curtains are fitted as a standard to ensure maximum operator safety, further to decreasing the total cycle time of each welding. Light curtains are integrated to protect them against collisions and as a result of an extremely accurate and well defined design. -

Energy saving technology

Big welding area and low power required: this is energetic efficiency! -

Innovative operator interface system

Accurate does not mean complicated: no other machine on the market is so "user friendly".

We have made a big effort in designing our video graphic to simplify any operation. Actually, there would be no need for operator's training.- Switching to your language is as simple as pressing a key.

- Parameters can be set to include up to 8 different welding steps.

- Tool movement graphic programming: no need to call us for a new tool!

- Monitoring of the "just in time" process by displaying welding diagrams.

- Constantly linked to CEMAS through the Teleservice system for diagnostics and customer's service on line.