CEMAS CHINA AT CHINAPLAS 2025

The exhibition take place in Shenzhen World Exhibition & Convention Center from 15th to 18th of April

CHINAPLAS 2025

Also this year CEMAS CHINA was present at Chinaplas 2025 the International Exhibition on Plastics and Rubber Industries. The trade fair alternate between Shenzhen (odd years) and Shanghai (even years) in the future, continuing to empower upstream and downstream plastics and rubber companies to uncover greater opportunities in the new phase of China's economic development.

SIMULTANEOUS MULTI-FIBER LASER WELDING TECHNOLOGY

We show the MF120 in action, the smallest standalone machine of our simultaneous multi-fiber laser welding machines. An optimal machine for the production of small components but also for laboratory tests, which allows the integration of electronic components in the process of joining by exploiting the precision and cleanliness of laser technology.

In order to satisfy even the most stringent and complex requirements, CEMAS laser system has been designed with a fully modular architecture. The different models of CEMAS laser machines (MF120, MF240, and MF960) will be able to respond to various needs for welding small, medium or large components.

SIMULTANEOUS MULTI-FIBER LASER WELDING TECHNOLOGY

We show the MF120 in action, the smallest standalone machine of our simultaneous multi-fiber laser welding machines. An optimal machine for the production of small components but also for laboratory tests, which allows the integration of electronic components in the process of joining by exploiting the precision and cleanliness of laser technology.

In order to satisfy even the most stringent and complex requirements, CEMAS laser system has been designed with a fully modular architecture. The different models of CEMAS laser machines (MF120, MF240, and MF960) will be able to respond to various needs for welding small, medium or large components.

VIBRATION WELDING MACHINE WITH HYBRID TECHNOLOGY

Our wide range of vibration welding machines can satisfy any possible welding request, from simple and small components to the most complex and biggest ones.

Hybrid technology (Infrared + Vibration) ensure a perfect joint, in terms of aesthetic and strength.

The introduction of the new MK2 generation allows to combine the production needs of reliability, speed and precision with management needs with the services of Data collecting and monitoring of the 4.0 Industry.

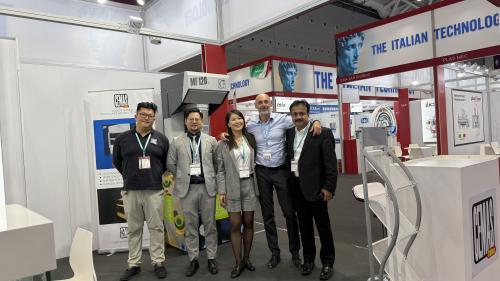

JOIN US!

Our team is at your complete disposal to discuss, share and evaluate your projects.