laser TECHNOLOGY, The future is now

Designed and Manufactured in Italy

All tooling is designed and manufactured in our Italian plant in parallel with the building of the machines.Complete control on production

The production structure allows CEMAS engineers and operators to have complete control over the manufacturing process and delivery times.OUR TECHNOLOGY

THE highest UNMATCHED MODULARITY ON THE MARKET

In order to satisfy even the most stringent and complex requirements, CEMAS laser system has been designed with a fully modular architecture.Currently our machines are the only one on the market provided with a single modularity system ("one by one" sources architecture), so as to allow the highest level of customization. This means that, according to the customer production needs, it is possible to equip the machine with a certain number of sources and, later, integrate more of them, one by one, up to reach the required quantity.

Indeed, thanks to a careful feasibility study, we are able to precisely estimate the number of sources necessary to complete the welding process of a specific product.

Working in this way, we can always guarantee the best quality-price ratio, allowing our customers to purchase only the components they really need.

-

MF960

One machine, all applications

The most complete simultaneous laser welding machine on the market.

Discover it

-

MF 120

MF 120TINY MACHINE, BIG capabilities

MF120 is a simultaneous multi-fiber laser welding machine ideal to realize both laboratory welding tests or mass-production of small parts. It can be equipped up to 12 laser sources and it is available with different power sizes: 150, 300, 450 and 600 W. The air cooling system of the machine allows a precise control of the temperature (in the order of 0.2° C) and it is able to reach high levels of efficiency. The press is servo controlled so as to assure an absolute precision and dynamic and, despite its dimensions, it is able to exert maximum clamping force up to 400 kg.

The brand-new version of MF120 has been designed with two possible press movement systems: ascending or descending. Thanks to this feature, this stand-alone machine can meet any production requirement.Laser output 12×50 W - 980 nm Lifting table stroke 500 mm Chilling system Air cooling tech Safety system Optical safety

double shutterFiber coupling Up to 12 bundles

5×10 W

10×5 W

15×3,3 WCommunication Serial communication Bus Power supply 3×400 V a.c.

We can also offer you air cooled single stand alone laser units and laser banks to be easily integrated in our other machines. Discover more

-

MF 30

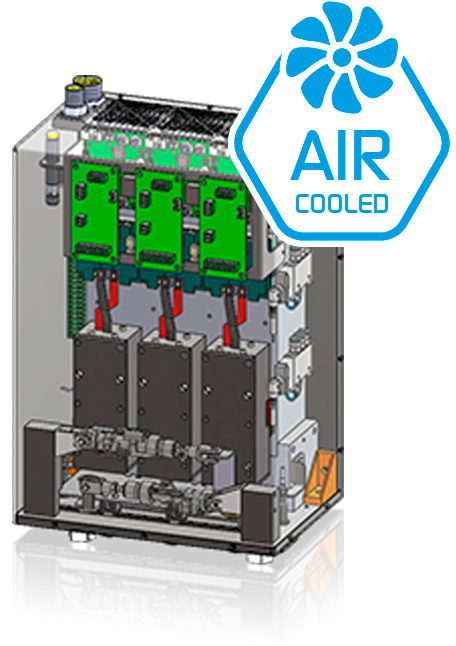

MF 30AIR COOLED LASER BANK

Equipped with three laser sources, it is ideal for small welding machines where it is not possible, or it is not convenient, to have a liquid chiller system. Each laser bank, it provides up to 150 W on the component to be welded.Laser output 3×50 W - 980 nm Chilling system Air cooling tech Safety system Optical safety double shutter Fiber coupling 3 Bundles

10×5 W

15×3,3 WCommunication Serial communication Bus Power supply 24 V d.c. -

MF 10

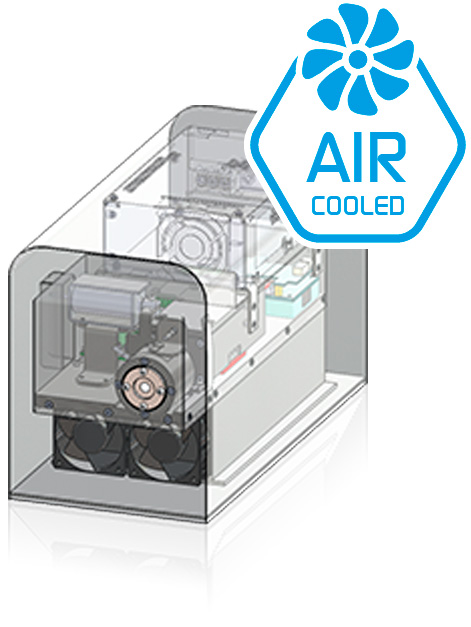

MF 10SINGLE STAND ALONE UNIT

This small laser welding machine is equipped with one laser source and one laser fiber. Its size is similar to a "shoe box", has been designed to be easily integrated in other machines of the same production line, where individual and small joints are necessary, even distant one from each other (e.g. for the bumper parking sensors).Laser output 1×50 W - 980 nm Chilling system Air cooling tech Safety system Optical safety double shutter Fiber coupling 1 Bundle

10×5 W

15×3,3 WCommunication Serial communication Bus Power supply Integrated 230 V a.c.

Why buy a CEMAS laser welding machine

-

Adaptable

Simultaneous multi-fiber laser welding guarantees a superior welding depth than the other laser applications. Indeed, is able to optimally weld, both on the aesthetic side and on the strength one, also components "not totally perfect", with some shape imperfections. -

Extremely clean

This is a non-contact welding technology. For this reason does not produce smokes, dusts, and particulate and it is totally wear-free. Indeed, in laser welding, the components to be welded are placed in "soft contact" and are not stressed during the production cycle (as it happens, for example, for the vibration welding). -

Efficient

The simultaneous multi-fiber system allows to heat instantly and concurrently the entire weld path, resulting in an extremely constant welding depth. In addiction, the zone to be melted is small and local, so there is no energy dispersion. -

Fast

Thanks to the simultaneous welding process, it is possible both to significantly reduce the machine cycle time and to ensure exceptional quality, cleanliness and flexibility (geometrical joint limitations are yet to be discovered!) of the welding process. -

Modular and flexible

This technology fits, like no other, to all production requirements, since it is possible to increase or decrease the number of laser sources according to the needs. -

Highly reproducible process

The precision clamping with no relative motion of parts during the welding cycle assures a highly repeatable welding process and consistent joint quality. -

Aesthetic in first place

This technology is dedicated in particular to the welding of rear lamps (in single or double cavity) and of all those components for which aesthetic side of the joining is simply essential. The flash is minimal.

- Highly customizable

- No compromise for quality

- Easy maintenance

- Ergonomic loading station

- Reliability

- Energy saving technology

- Innovative and user friendly UI

Cutting edge technology and fully equipped machines as standard. Discover more

-

Highly customizable

Many standard features included in our machines are optionals for competitors and, should this not be enough, just turn the page to discover a full range of over 60 optionals for your tailor-made machines. -

No compromise for quality

All components used by CEMAS are from world leading suppliers and never sub-brands.

Safety is our ultimate goal, as well as a prompt availability of spares worldwide. -

Easy maintenance

The use of the latest-generation electronic components has resulted in a remarkably smaller control panel, and in positioning the hydraulic unit below the control panel for the 240 Hz machines. This change has totally cleared an inner compartment and has made tooling maintenance and set up operations easier. -

Ergonomic loading station

Special care was devoted to the manual loading steps of the process, both for small and large machines: to minimize effort on the backbone, the loading/unloading area was kept as close as possible to operator. There are no machines of the same class available on the market where this distance is so small. -

Reliability

Light curtains are fitted as a standard to ensure maximum operator safety, further to decreasing the total cycle time of each welding. Light curtains are integrated to protect them against collisions and as a result of an extremely accurate and well defined design. -

Energy saving technology

Big welding area and low power required: this is energetic efficiency! -

Innovative operator interface system

Accurate does not mean complicated: no other machine on the market is so "user friendly".

We have made a big effort in designing our video graphic to simplify any operation. Actually, there would be no need for operator's training.- Switching to your language is as simple as pressing a key.

- Parameters can be set to include up to 8 different welding steps.

- Tool movement graphic programming: no need to call us for a new tool!

- Monitoring of the "just in time" process by displaying welding diagrams.

- Constantly linked to CEMAS through the Teleservice system for diagnostics and customer's service on line.

ApplicationS

Aesthetic in first place

Laser welding technology does not produce smokes, dusts, and particulate and it is totally wear-free. Moreover, during the welding process the components are placed in "soft contact" and are not stressed (as it happens, for example, for the vibration welding).For this reason, laser welding is currently the most suitable welding process for component with internal hi-tech electronic components that must not be strained in any way.

The Laser welding technology

The term "laser" is an acronym for Light Amplification by Stimulated Emission of Radiation, and describes a physical process: an amplified concentration of light energy at a specific wavelength, capable of focusing on a specific point or on a narrow beam spread over a long distance.

The infrared radiation, driven by waveguides, passes through the transparent part and heats the absorbent component.

Reached the melting point, the absorbent component, according to the principle of conduction, heats the transparent one, allowing the real welding.

Finally, to ensure a perfect welding and sealing quality, the two components are pressed together by a mechanical press.

How does it work

Using the "diode laser system" (usually at 980 nm, but other wavelengths are possible) the welding process with laser irradiation allows to join a plastic absorbent component with a transparent one (so called as it is transparent to the infrared wavelength used).The infrared radiation, driven by waveguides, passes through the transparent part and heats the absorbent component.

Reached the melting point, the absorbent component, according to the principle of conduction, heats the transparent one, allowing the real welding.

Finally, to ensure a perfect welding and sealing quality, the two components are pressed together by a mechanical press.

SIMULTANEOUS LASER WELDING SYSTEM

CEMAS knows how

Thanks to our know-how gained in over 30 years of experience in plastic industry, nowadays we are one of the most proficient company in laser welding field. Integrating our machines by using top class materials and components, manufactured by the world leading suppliers, we are able to develop and produce welding machines capable to satisfy every production requirements.

Each machine is entirely conceived and developed by our R&D department and it respects the most stringent qualitative and technical standards. Our laser tools are designed and manufactured entirely in CEMAS main Italian plant, where we also assembly our machines. This production structure allows our engineers and operators to have a complete control over the entire project development.

Each machine is entirely conceived and developed by our R&D department and it respects the most stringent qualitative and technical standards. Our laser tools are designed and manufactured entirely in CEMAS main Italian plant, where we also assembly our machines. This production structure allows our engineers and operators to have a complete control over the entire project development.

Accurate tool for perfect welding

We take care of our tooling

Our machines are designed to optimally manage all the welding process variables, in order to ensure high standards of efficiency and reliability, with a low energy consumption.To realize machines capable to respond to any production expectations, the tool manufacturing is preceded by a careful virtual modelling and prototyping process. The beam tracing process, using CAD finite element analysis software, allows our engineers to simulate how the light acts in the waveguide. This process is fundamental to design efficient tools without wasting time and economic resources.

This process is fundamental to design efficient tools without wasting time and economic resources.