Thanks to the know-how and experience of our team, we take care of our customers during the entire production cycle, from initial design to final implementation of complex components: we develop for you and with you the most efficient welding technology for your needs by a "customization" process of the entire range of machines and tools.

-

Consulting

We provide a "consulting service" that allows anyone who wants to weld plastic material or components to request a consultation to our specialists, and find with them the best technical solution to weld their product.

-

-

Feasibility

Our engineers analyze customer's product 3D data, specifications and materials, and then offer technical suggestions in order to improve it and make it "feasible", choosing the most suitable welding technology, able to give the best results.

-

-

Prototyping

Our R&D department designs and manufactures several kinds of equipment for laboratory tests, in order to make welding trials on new shapes, new materials or new products, also studying and developing new welding technologies.

Our services

-

Pilot area

Pilot areaA simulating area where the projects could be developed from the beginning.

We offer to our customers the utility of a simulating area (500 m²) inside our workshop, where the projects could be developed, starting from the initial sampling, passing through simulation test, arriving to the start up.

A 250 m² area is available as a warehouse, in order to make easier the logistics management and ensure customers privacy. Moreover, our customers can enjoy an office next to the workshop, a meeting room and more other services (Free Wi-Fi connection, printers, CAD stations, etc).Available inItaly - Brasil - Germany - Turkey - China -

First aid on the spot

First aid on the spotTechnicians and welding specialists ready to reach the customer on the spot, all over the world.

In case our customer needs a "first aid on the spot", all the five CEMAS production plants are organized for always having some technicians and welding specialists available and ready to leave within 48 hours from the customer call, to reach him on the spot, all over the world.

We are able to offer a personalized service, by providing technicians specialized in different welding technologies and products.Available inItaly - Brazil - Germany - Mexico - Turkey - China -

Rent a machine

Rent a machineWe have always a stock of our standard machines ready to be delivered.

If you are lucky enough to face a sudden increase in production, but at the same time you don't want to deal with the costs of purchasing a new machine, we can propose you a special service that is right up your alley: the "rent-a-machine"!

We offer rental and leasing contracts. Contact us to learn more!Available inItaly - Brazil - Germany -

Prompt delivery

Prompt deliveryA 240Hz vibration machine is always available in our plant and ready to be delivered.

At least one machine for each model of our 240Hz range of vibration welding machines, in Cemas standard colors, is always available in our plant and ready to be delivered to the customer.

Actually, we have often been able to deliver also our 100Hz machines in less than one month! Multinational company is often synonymous with "longer bureaucracy, slower feedback". For us, reactivity and flexibility are key principles.Available inItaly (vibration machines are 100% made in Italy) -

Design department

Design departmentWe offer always targeted solutions thanks to our engineers specialized in different areas.

Our company has always chosen not to be just an "assembling company", but to be able to conceive and design its own welding machines and welding equipment, constantly new and cutting-edge.

For this reason, all our plants are provided with a design department and our engineers are specialized in different areas: this allows us to offer to our customers always targeted solutions, both in case of new projects that in case of modifications of the existing ones.Available inItaly - Brazil - Germany -

Teleservice

TeleserviceA simple and economical maintenance of machines and remote facilities.

Teleservice is the first option to consider when it's needed to perform a simple and economical maintenance of machines and remote facilities.

This allows to quickly recognize the overall need of our customer, performing diagnostics and maintenance from anywhere in the world via a telephone connection and avoiding plant downtime and travel and personnel costs resulting from interventions on site.Available inItaly - Brazil - Germany -

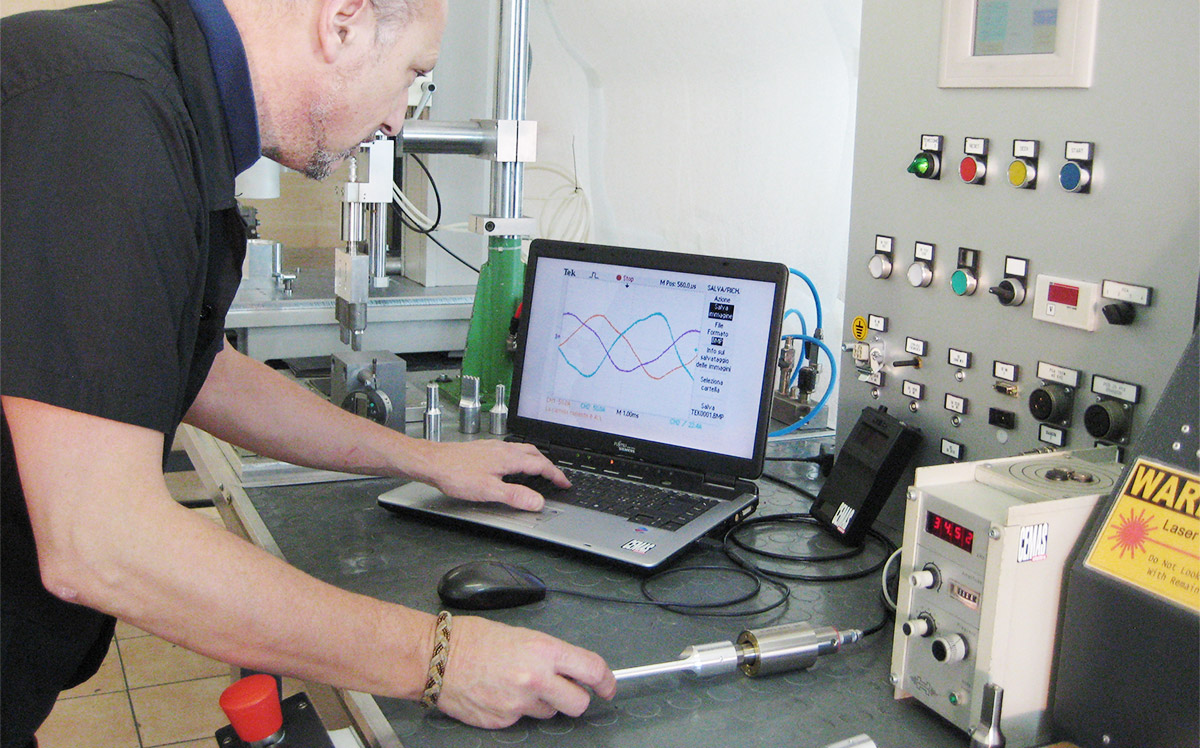

Applications lab

Applications labThe place where to test our customers' new welding solutions.

In our Applications lab we are provided with standard and special equipment, and we carry out several welding tests on new products and new materials, by using different welding technologies (ultrasonic, vibration, laser, infrared etc).

Our Applications lab is the place where, upon customer request, our researchers study, design and build prototype equipment to test new welding solutions.Available inItaly - Brasil - Germany - Mexico - Turkey - China -

Metrological lab

Metrological labAdvanced technologies and equipment for an easy verification of the highest product quality.

For quality purposes, we use advanced technologies and equipment, such as Coordinate Measuring Machine (CMM), that allows an easy verification of product quality by performing 3D inspections, tool certifications, CAD comparison, dimensional analysis and report, and more.

Our Metrological lab not only ensure the highest product quality to our customers, but also helps our company to maximize its efficiency and improve its processes.Available inItaly - Brazil - Germany - Turkey